Description

Brand - RINGSPANN

Part Number - FXRU 170 - 63 MX RINGSPANN

Category - Integrated Freewheels FXRU

Principal Dimensions & Specifications (Metric):

Maximum Bore Diameter (d) - 130 mm

Srandard Bore Diameter (d) - 110 mm

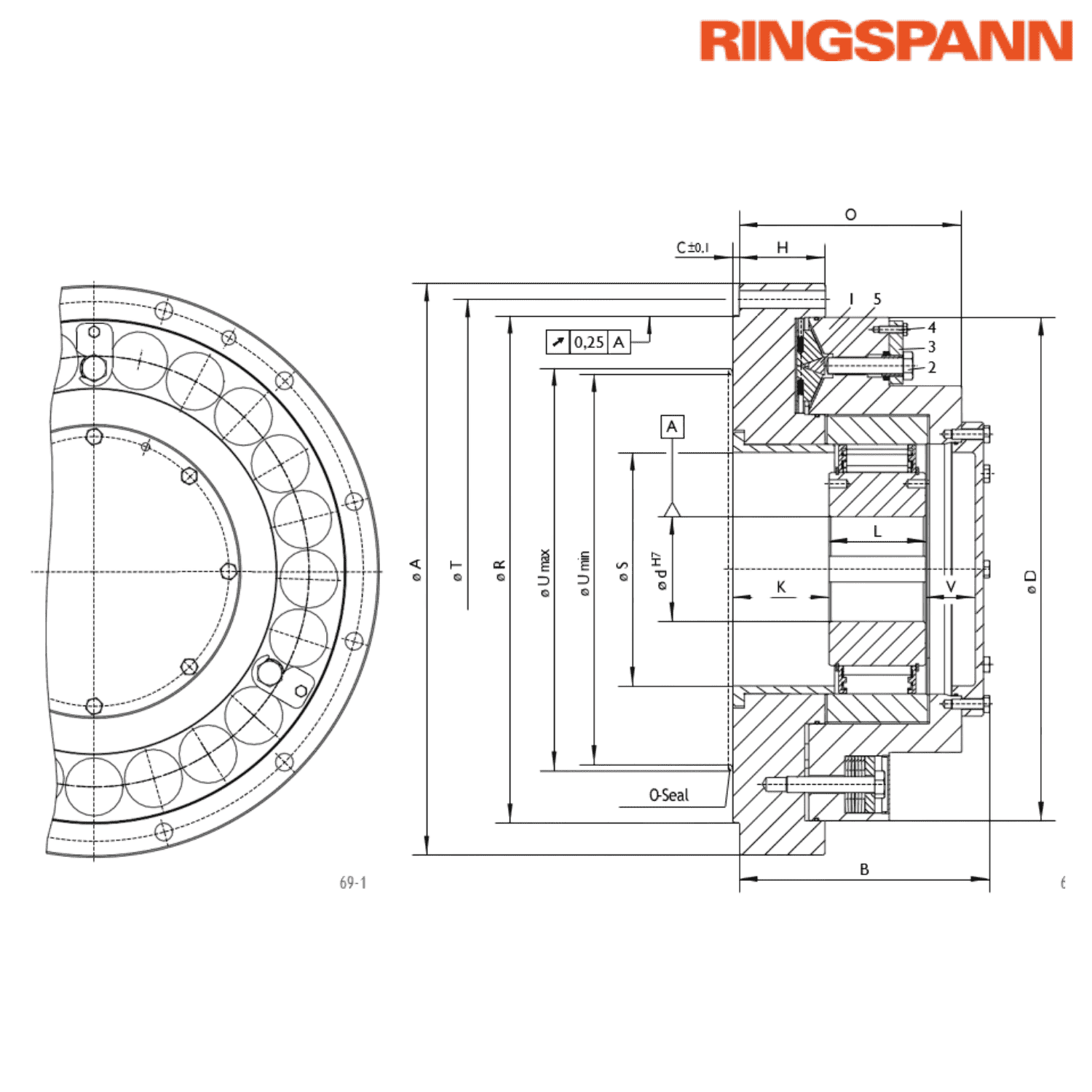

Dimension (A) - 500 mm

Dimension (B) - 232 mm

Dimension (C) - 6 mm

Dimension (D) - 445 mm

Thread (G) ** - M 16

Dimension (H) - 89 mm

Dimension (K) - 100 mm

Dimension (L) - 80 mm

Dimension (O) - 205 mm

Dimension (R) - 425 mm

Dimension (S) - 196 mm

Dimension (T) - 473 mm

Minimum Dimension (U) *** - 250 mm

Maximum Dimension (U) *** - 425 mm

Dimension (V) - 36 mm

Number of Fastening Holes (Z) ** - 6 mm

Weight - 197 kg

Slipping Toeque (MR) - 19000 Nm

Sprag Lift-off at Inner Ring Speed - 250 RPM

Maximum Speed Inner Ring Freewheels - 2700 RPM

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of fastening holes for screws G on pitch circle T

*** Area for O-ring sealing

Features:

• Integrated Freewheels FXR are sprag-type freewheels without built-in bearing support, featuring sprag lift-off design (X)

• The sprag lift-off mechanism ensures no contact during high-speed inner ring rotation, resulting in wear-free operation

• Upon stoppage, the full backdriving torque often gets concentrated on a single backstop, which can overload it

Application as: Backstop (For continuous conveyor systems that use multiple drives, each fitted with its own backstop)

Torques:

• IIntegrated Freewheels FXRU are equipped with a preset slipping torque (MR) for the built-in torque limiter

• The static backdriving torque (ML) of the installation, even under overload conditions — must never exceed the combined MR values of all installed freewheels

Mounting:

• Integrated Freewheels FXRU do not have bearing support

• The runout (T.I.R.) between the pilot diameter (R) and shaft diameter (d) must not exceed 0.25 mm

• Dimension C is the reference depth for the freewheel installation

• The centering depth of the customer’s attachment part must be at least C + 0.2 mm

• The pilot diameter R must have a tolerance of ISO H7

• The shaft diameter must conform to ISO h6 or j6 tolerance

♦ ♦ Images are for representation purposes only

Part Number - FXRU 170 - 63 MX RINGSPANN

Category - Integrated Freewheels FXRU

Principal Dimensions & Specifications (Metric):

Maximum Bore Diameter (d) - 130 mm

Srandard Bore Diameter (d) - 110 mm

Dimension (A) - 500 mm

Dimension (B) - 232 mm

Dimension (C) - 6 mm

Dimension (D) - 445 mm

Thread (G) ** - M 16

Dimension (H) - 89 mm

Dimension (K) - 100 mm

Dimension (L) - 80 mm

Dimension (O) - 205 mm

Dimension (R) - 425 mm

Dimension (S) - 196 mm

Dimension (T) - 473 mm

Minimum Dimension (U) *** - 250 mm

Maximum Dimension (U) *** - 425 mm

Dimension (V) - 36 mm

Number of Fastening Holes (Z) ** - 6 mm

Weight - 197 kg

Slipping Toeque (MR) - 19000 Nm

Sprag Lift-off at Inner Ring Speed - 250 RPM

Maximum Speed Inner Ring Freewheels - 2700 RPM

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of fastening holes for screws G on pitch circle T

*** Area for O-ring sealing

Features:

• Integrated Freewheels FXR are sprag-type freewheels without built-in bearing support, featuring sprag lift-off design (X)

• The sprag lift-off mechanism ensures no contact during high-speed inner ring rotation, resulting in wear-free operation

• Upon stoppage, the full backdriving torque often gets concentrated on a single backstop, which can overload it

Application as: Backstop (For continuous conveyor systems that use multiple drives, each fitted with its own backstop)

Torques:

• IIntegrated Freewheels FXRU are equipped with a preset slipping torque (MR) for the built-in torque limiter

• The static backdriving torque (ML) of the installation, even under overload conditions — must never exceed the combined MR values of all installed freewheels

Mounting:

• Integrated Freewheels FXRU do not have bearing support

• The runout (T.I.R.) between the pilot diameter (R) and shaft diameter (d) must not exceed 0.25 mm

• Dimension C is the reference depth for the freewheel installation

• The centering depth of the customer’s attachment part must be at least C + 0.2 mm

• The pilot diameter R must have a tolerance of ISO H7

• The shaft diameter must conform to ISO h6 or j6 tolerance

♦ ♦ Images are for representation purposes only