Best Bearing for Steel Industry: FAG Bearings & INA Bearings

The metal industry plays an important role in the development of the world’s economy, and its close ties to different industrial sectors makes it very crucial.

The Iron and steel industry is one in every of the severe environments within which power transmission equipment are expected to perform expeditiously.

With the escalating elevation of maintenance fused by pressure to scale back operative prices, we’ve identified many areas for potential savings during this strenuous trade and explained how these savings can be achieved.

Bearings for production of Steel

Each stage in the production of steel dispenses totally different issues and needs differing solutions to be enforced.

The operative surroundings sees high temperatures, serious loads, low speed and exposure to sintered particles, all of which usually cause premature bearing failure on traditional pallet wheels and inboard rollers.

Probable contamination conjointly results in a lot of frequent greasing, that also incurs additional prices.

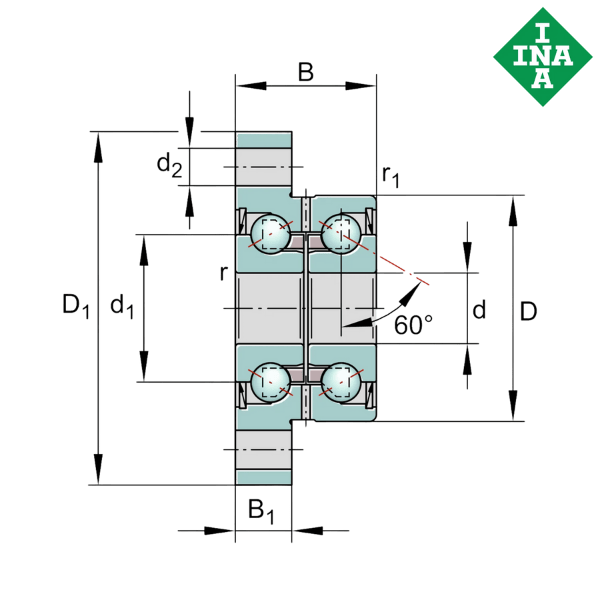

Rolling bearings for iron and steel mills need to endure diverse and extreme operative conditions, amongst that are high temperatures, both high and low rotational speeds, serious loading also as exposure to wetness, exhausting particulates and corrosive foreign matter.

Schaeffler : FAG & INA Bearings

Schaeffler has been a noted development partner for the metal trade for several years.

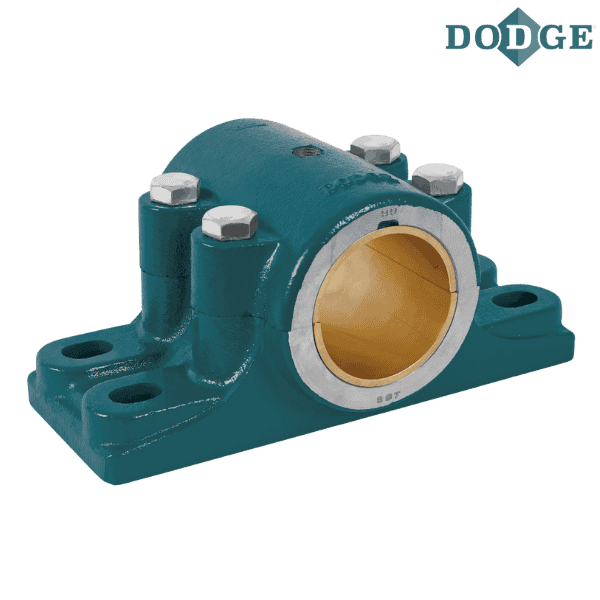

We at Santiniketan Enterprises offer a whole variety of Schaeffler products, designed specifically to deliver reliable and continuous operation below these conditions. Applications on continuous casting machines, to backup rolls and work rolls on rolling mills FAG & INA Bearings are widely used.

Best resolution is; rather than a visible bearing, use a bearing with particularly robust seals.

The various Schaeffler developed encapsulated styles effectively prevents scale from penetrating into the bearing, high quality grease also has outstanding resistance to heat and pressure. Re-lubrication of the bearing units is unnecessary.

Use of Bearings in the production of Steel – Problems & Solutions

Basic gas Furnaces (BOFs) and converters – effectively the melting pot stage of the process that sees some very troublesome operative conditions: warm temperature, serious loads, ultra-low speed and oscillation.

The prime issue is that the time needed to revive the inboard bearings, with sudden failures inflicting giant production losses.

By introducing Ultra-Large split bearings for trunnions, the maintenance may be refrained from removing the bull gear. This reduces maintenance prices and production down time by some thirty fifth.

Continuous casting machines – Here the liquified steel solidifies and starts its journey towards the rolling mills. Once more the operative conditions involve heat, serious hundreds, water vapor, ultra-low speed, scale and skew positioning.

The most problems during this space of production square measure uneven wear and flaking or cracking of the outer raceway.

These will cause the enlargement of roll gaps and surprising mechanical system failure. Schaeffler has developed a spread of sealed spherical roller bearings specifically designed to forestall the ingress of contamination and supply vital enhancements in bearing sturdiness.

Rigorous testing has shown that this may cut back maintenance prices and improve overall production figures.

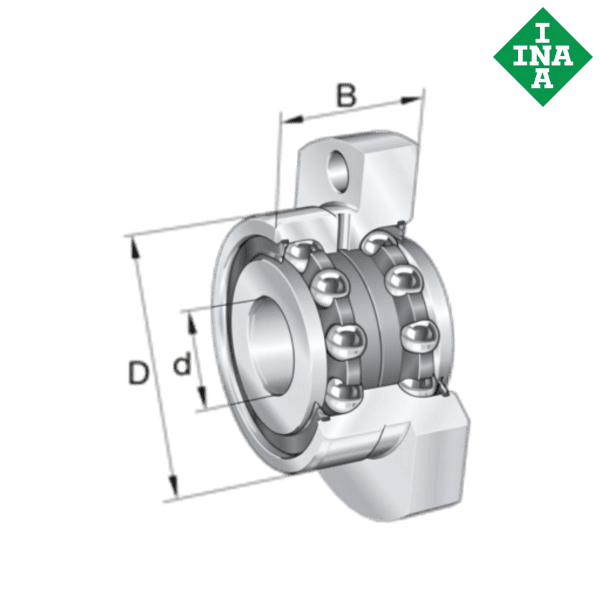

The Tapered Roller / Cylindrical Roller Bearings, split roller bearings and SWR Bearings square measure all designed to be used within the continuous carving surroundings.

Rolling mills – These will include Plate mills, Table Rollers, Rolling mills, Hot Strip mills, Cold rolling mills, Multi-roll rolling cluster mills and Skin pass mills – This space of production may be an especially troublesome surroundings, and needs specialist style options to confirm that the machinery keeps moving and production continues.

Schaeffler has developed a range of bearings specific to every task and checked all on test rigs that are designed to simulate the rigors of the important operating surroundings before field trials were used to make sure performance.

By exploiting its Super TF steel, the expected service lifetime of the bearing, compared to a standard steel part, has been extended by an element of two. when the protection improvement, the access of water and foreign bodies is probably reduced and also the overall bearing life is 3 times that of the quality item.

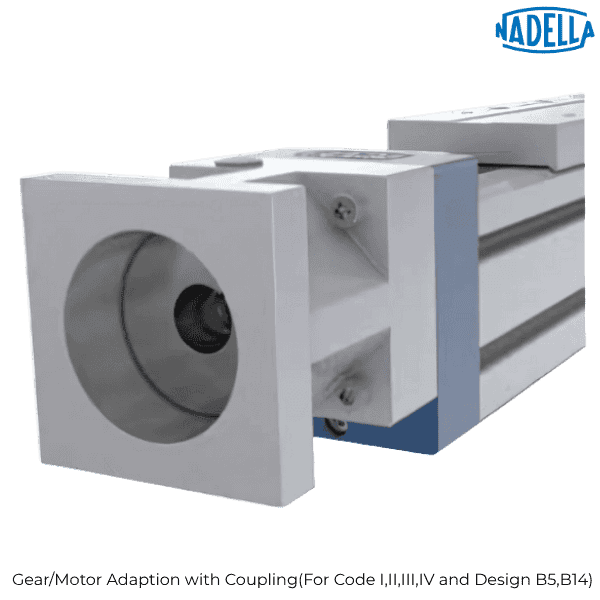

The use of ball bearing, roller bearing, Radial insert bearing, railway line system, Counterstay system has seen intensive enhancements in the performance of the bearings in this area of production.

Super TF steel has excellent resistance to contamination by foreign bodies, which ends up in longer service life, and conjointly cuts down the assembly time and maintenance prices.

SANTINIKETAN ENTERPRISES – Who are we?

Our Extensive understanding of product lines provide support to our customers through economical, selecting the right product and high operative effectiveness.

We are known across various locations for being the foremost cost-effective, genuine and timely solution provider for all your industrial needs. We at Santiniketan Enterprises are committed to serve global markets in Asia and the Middle East with 25+ global brands, and over 10,000 unique SKUs. You can rely on us for a fast, convenient and penny-wise delivery of your goods.

We have also provided every product description with specification and brochures on our web site to produce you with in-depth data concerning all different kinds of bearings that we provide.