Understanding Bearing Sealing and Internal Clearance: A Guide to Enhanced Performance

In the world of precision engineering, even the smallest components can have a huge impact. Rolling bearings are no exception. Two factors — sealing and internal clearance — are critical to optimizing performance, reducing wear, and extending service life. Here's what you need to know.

Integral Sealing: Keeping Contaminants Out and Lubrication In

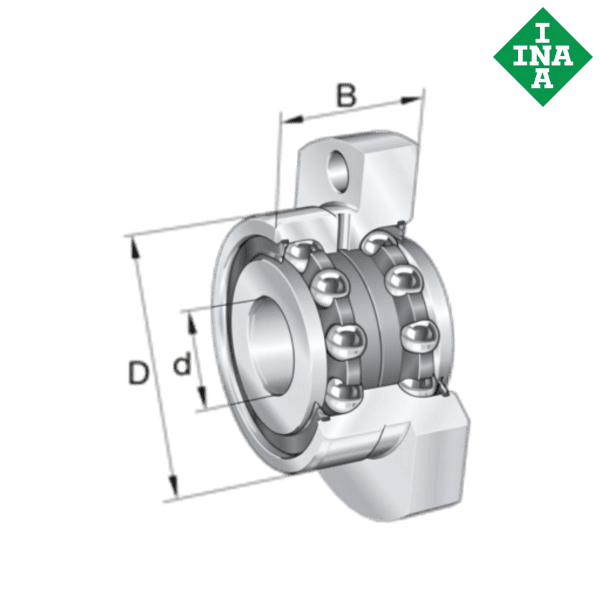

• Feature a small gap between the shield and inner ring

• Best suited for clean environments or where low friction is crucial (e.g., high-speed applications)

• Do not contact the rolling surface, so they allow free movement with minimal resistance

Sealed Bearings

Designed for better sealing than shields, they are ideal for environments with moderate contamination.

• Make direct contact with the bearing ring

• Effective where moisture or dust is present

• Contact one of the bearing rings, but with lower resistance

• Combine good sealing with the ability to run at higher speeds

• Do not touch the rolling elements

• Provide sealing performance close to shields, but with improved dust and fluid resistance

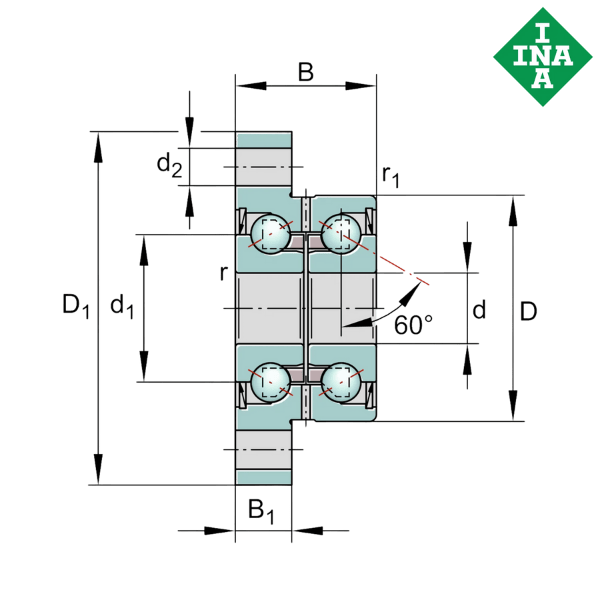

Internal Clearance: Precision Matters

• Radially (side-to-side)

• Axially (end-to-end)

(Fig. 5 clearly shows radial vs axial internal clearance.)

Why Initial Clearance Is Larger Than Operating Clearance

Most bearings are installed with a tight fit on the shaft or in the housing, which compresses the rings. When the bearing heats up during operation, thermal expansion further reduces this clearance. That’s why initial internal clearance must be greater—to compensate for:

• Interference fits during mounting

• Heat generation in operation

Selecting the Right Clearance

Choosing the correct internal clearance is critical for optimal performance. Bearings are available in different clearance classes, as standardized by ISO, ranging from tighter to looser fits. SKF uses suffixes in part numbers to indicate when a bearing's internal clearance deviates from the standard (normal) class Shown in the table below.

| ISO clearance class | SKF designation Suffix | Internal clearance |

| - | C1 | Smaller than C2 |

| Group 2 | C2 | Smaller than Normal |

| Group N | - | Normal |

| Group 3 | C3 | Greater than Normal |

| Group 4 | C4 | Greater than C3 |

| Group 5 | C5 | Greater than C4 |

Conclusion

Both sealing design and internal clearance are fundamental to bearing performance. The right sealing keeps contaminants out and lubrication in, while properly selected internal clearance ensures smooth, stable operation under load and temperature changes. Understanding these features helps you select bearings that last longer and perform better—even in demanding conditions. For more details please visit this page.