FAG – Company Introduction

FAG Bearings India Ltd was established in the year 1962. FAG along with INA together became the world’s second largest rolling bearing manufacturers. In the year 2017, the company changed its name to Schaeffler India Limited.

The company has its headquarters and manufacturing facilities in Vadodara. The second plant in Vadodara at Savli produces next generation deep groove ball bearings and large size roller bearings also sold under the name of FAG.

Schaeffler’s third state-of-the-art plant is located at Talegaon near Pune, and manufactures engine and transmission components for front accessory drive system, chain drive systems, valve train, shift systems and a range of needle roller bearings and elements, under the brand INA.

The fourth manufacturing location is based out of Hosur, producing clutch systems and dual mass flywheels for passenger cars, light commercial vehicles, heavy commercial vehicles and tractors which are sold under the brand of LuK.

FAG quality management is operated on a daily basis in the company and is a dynamic process. This makes sure that they work on making their products better. The company manufactures and sells ball and roller bearings and various other related components in the country.

FAG Products :

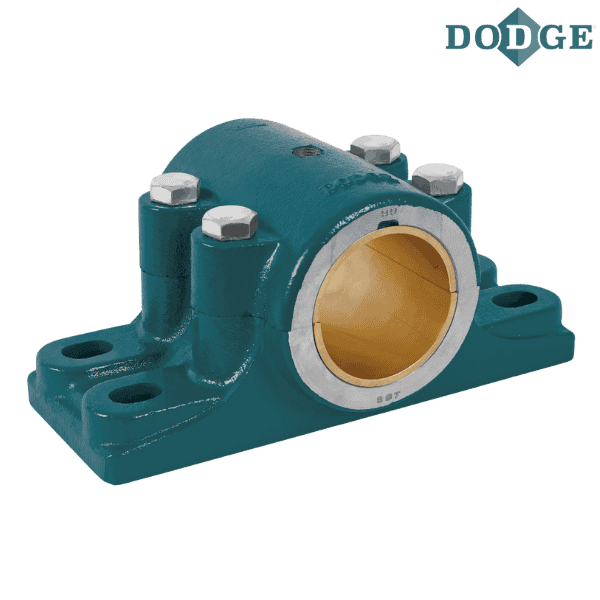

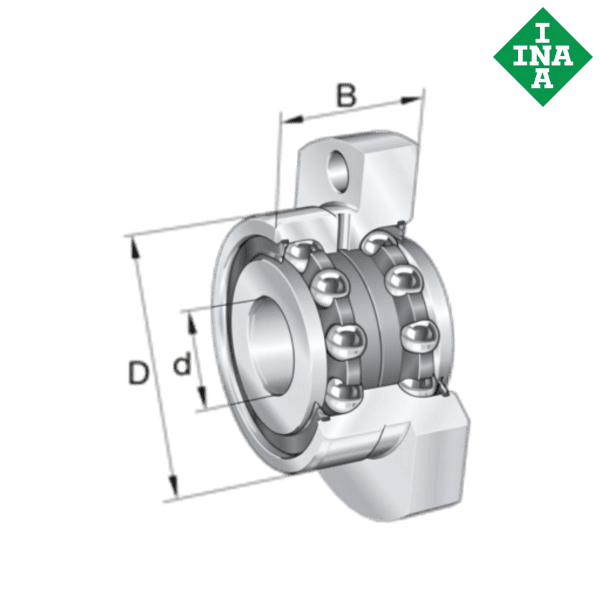

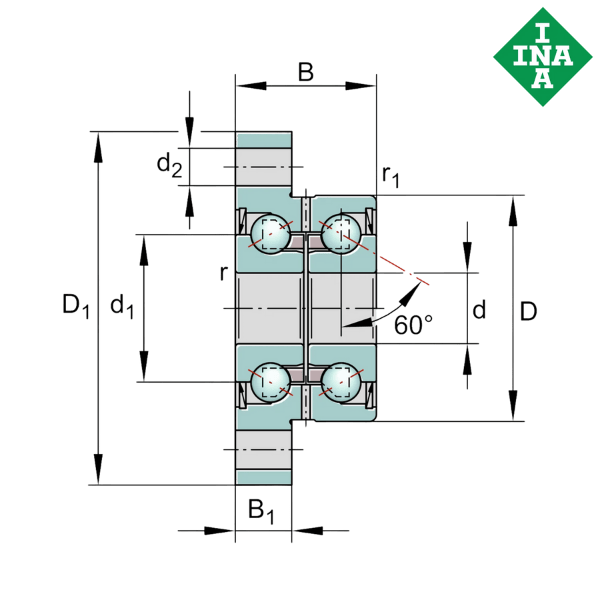

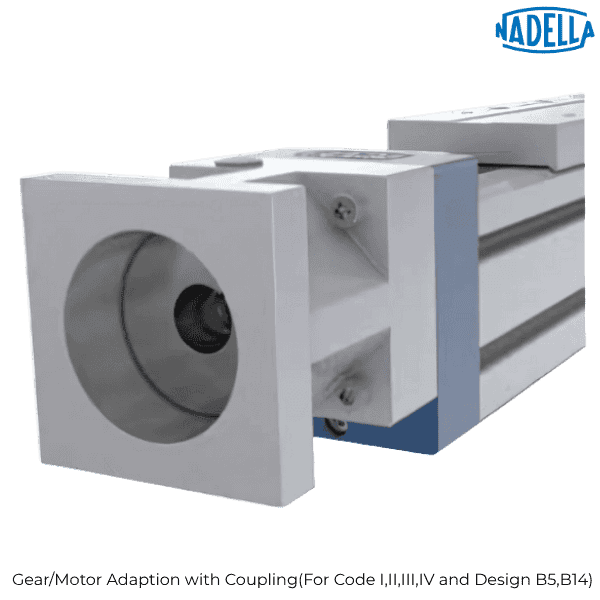

They produce rolling bearings, spherical plain bearings, plain bearings and linear products under the brand names INA and FAG across the world.

The company covers applications in more than sixty industrial sectors and out of those, a large number of automotive applications are covered by more than 40,000 volume produced catalog products.

Under the maintenance products the company covers: mounting & dismantling, lubrication, alignment and condition monitoring. The company has developed their own range of Arcanol rolling bearing greases that includes a large number of different lubricants.

FAG Products Applications :

The company offers their products and services to construction machinery, electrical engineering, fluid technology, power generation, steel plants, motor cycles, textile machinery, pulp and paper and various other industries.

They also export their products to a large part of Europe, the United States and Asia. Their international customers that use their Indian products are: Daimler Chrystler, Volvo, Volkswagen, Renault, Otis, Voith and General Dynamics. The company is also recognized as the most reliable source for numerous critical applications that include: traction motors, journal roller bearings, transmission, auxiliary motors and many others by one of their important customers, the Indian Railways.

Now if you are looking for FAG distributors or specifically INA distributors then you are exactly at the right place. You can rely on us for your safe and quality delivery of goods as we are known as the best Industrial goods distributor in India.

Why Choose Santent Distributors?

Our Comprehensive knowledge of product lines provide support to our customers through cost efficiencies, selecting the correct product and high operative effectiveness. We are known across various locations for being the most cost-effective, genuine and timely solution provider for all your industrial needs. We are the Santent Group of Companies, committed to serve global markets in Asia and the Middle East with 25+ global brands, and over 10,000 unique SKUs. You can rely on us for a fast and cost effective delivery of your goods.

Get Pricing information Now, here.

Frequently Asked Questions ( FAQ ) :

Q: When selecting bearings, what should we need to consider ?

A : The precision of the bearings (dimension tolerance, loading rate), internal clearance and hardness under heat treatment, structure of cage and material.

Q:The advantage of FAG Bearing ??

A :

(1) Reduce friction and wear.

To prevent metal contact and reduce friction and wear in the contact part of the bearing ring,

rolling body and maintainer.

(2) Prolong fatigue life.

The rolling fatigue life of the bearing, in the rotation, the rolling contact surface lubrication good,

then extended. Conversely, the oil viscosity is low, the lubricating film thickness is not good,

then shortened.

(3) Exhaust friction heat and cooling.

The circulation to oil method can be used to exhaust the heat generated by friction, or from external

heat, cooling. Prevent the bearing from overheating and prevent the lubricating oil from ageing itself.

Q: What are the Application area of FAG Bearings ?

A : It can cover almost all mechanical industries, including robotic systems, lathes, tools, automobiles, large equipment, and so on.