Essential Guide to Types, Functions, and Design (With Illustrations) Rolling bearings are indispensable components in modern mechanical systems. From enabling smooth rotation to supporting heavy machinery, their efficiency, precision, and durability make them essential in various industries. In this blog, we explore the fundamentals of rolling bearings, their key classifications, and how they operate—with image references for better understanding.

Why rolling bearings are used?

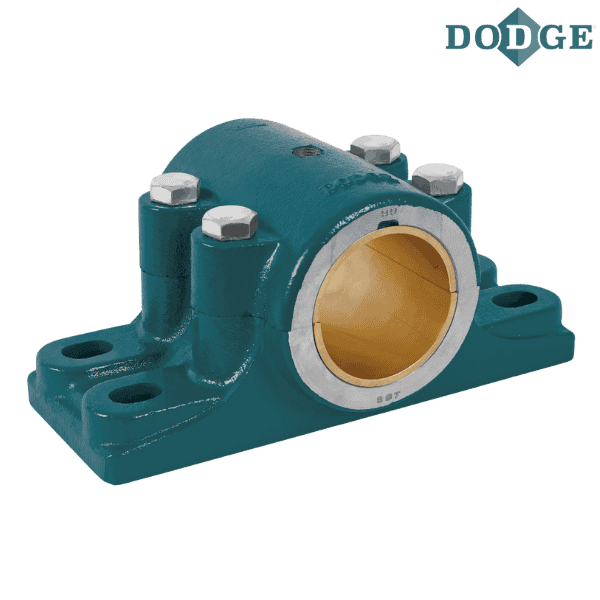

Rolling bearings are designed to support and guide rotating or oscillating machine components—such as shafts, axles, or wheels —while keeping friction to a minimum (Fig. 1). By using rollers or balls, they significantly reduce friction compared to plain sliding mechanisms.

These bearings are known for:

- High precision

- Capability to handle high rotational speeds

- Reduction in noise, heat, and energy loss

- Cost-efficiency and standardization (easy to replace)

This combination of benefits makes rolling bearings a smart choice for engineers seeking performance and longevity.

Ball vs. Roller Bearings

Rolling bearings come in two fundamental types based on their rolling elements:

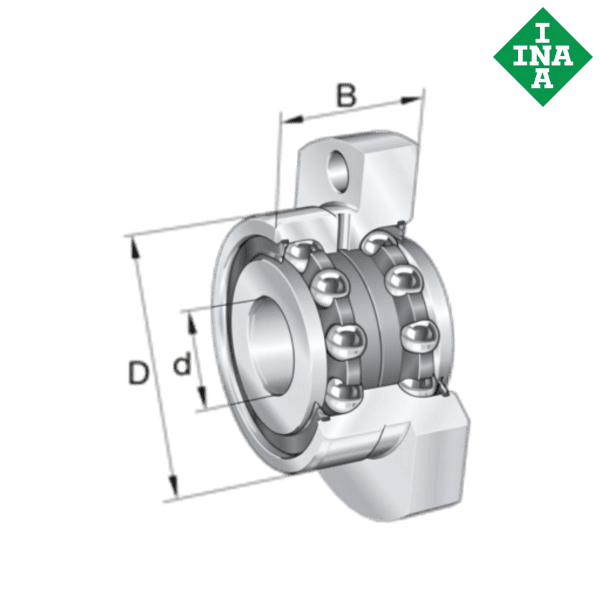

Ball Bearings

• Use spherical balls

• Make point contact with the raceways

• Low friction and suitable for high speeds

• Limited load-carrying capacity

• Fig. 2 illustrates point contact between balls and raceways. Under load, this contact becomes an elliptical area

Roller Bearings

• Use cylindrical or tapered rollers

• Make line contact with raceways

• Can support heavier loads

• Lower speed limits due to increased friction

• Fig. 3 shows how the line contact expands into a rectangular area under load, allowing higher load support

Radial vs. Thrust Bearings

Bearings are also categorized based on the direction of the load they carry:

• Handle forces acting perpendicular to the shaft

• Some support only radial loads, while others can also accommodate axial loads in one or both directions

• Refer to Fig. 4 for radial bearings

• Handle forces along the axis of the shaft

• Depending on their design, may support axial loads in one or both directions

• Some can handle radial loads as well (combined load type)

• Not suitable for high speeds like radial bearings

• Fig. 5 shows thrust bearing for pure axial load

• Fig. 6 for combined radial and axial load handling

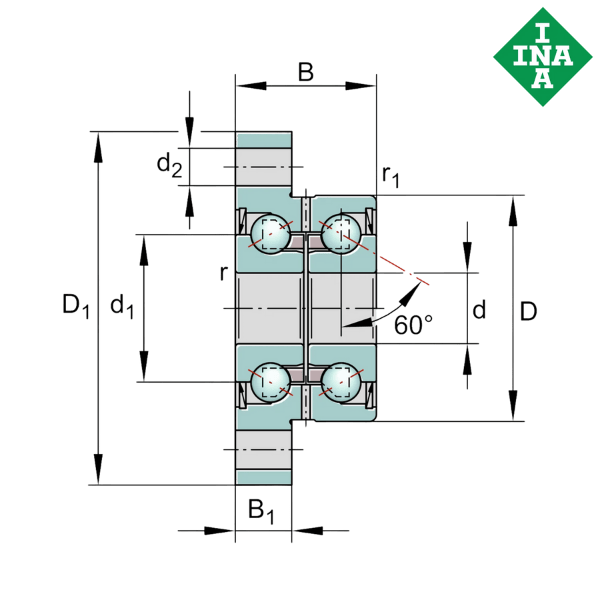

The contact angle helps determine the bearing type:

• Bearings with a contact angle ≤ 45° → Radial Bearings

• Contact angle > 45° → Thrust Bearings

• See Fig. 7 to understand how the contact angle distinguishes between bearing types

📘 Conclusion

Rolling bearings—whether ball or roller, radial or thrust—offer versatile solutions for reducing friction and efficiently supporting loads. Their design, material, and geometry ensure optimal performance in applications ranging from high-speed motors to heavy-duty industrial machines.

To explore these concepts visually and for a clear understanding of contact types, load directions, and structural differences visit here.