Key Components of a Rolling Bearings

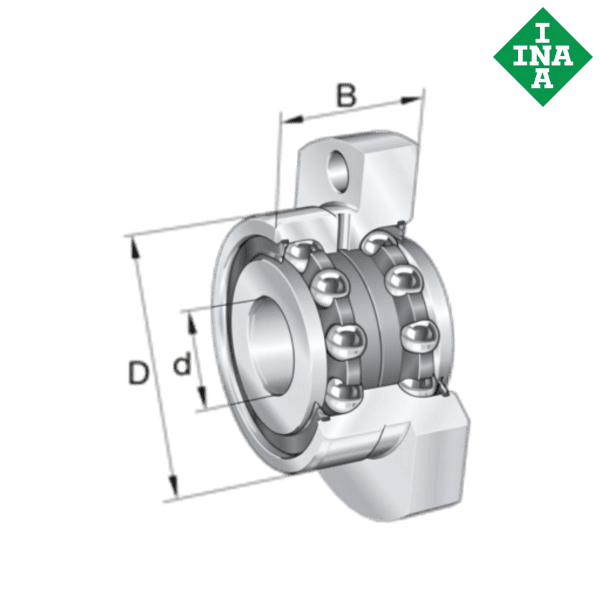

A typical rolling bearings are made up of four essential parts (Fig. 1):

- Inner Ring – Fits around the shaft and rotates with it

- Outer Ring – Mounted in the housing and remains stationary

- Rolling Elements – Balls or rollers that carry the load

- Cage – Holds the rolling elements evenly spaced

Rolling bearings are come with built-in seals or shields on one or both sides. These “capped” bearings are factory-filled with grease, offering a space-saving and cost-effective solution compared to external sealing systems. They help to prevent contamination and eliminate the need for additional lubrication, making them ideal for compact applications.

Bearing Rings: Built to Resist Fatigue

The rolling elements—whether balls or rollers—are responsible for transmitting load between the inner and outer rings. These elements are usually made from the same high-grade steel as the rings to ensure compatibility and strength.

However, in applications where lower friction, higher speeds, or electrical insulation is needed, ceramic rolling elements are used. Bearings with ceramic components are known as hybrid bearings.

Bearing Cages:

In rolling bearings, the cage may not be the most visible component—but it plays a critical role in ensuring the bearing runs smoothly, efficiently, and reliably.

What Does a Bearing Cage Do?

The cage in a bearing serves several important purposes:

- Separates the rolling elements to minimize contact and reduce heat caused by friction

- Maintains uniform spacing between rolling elements to ensure even load distribution

- Guides the rolling elements when they are in the unloaded area of the bearing

-

Holds the rolling elements in place during assembly or disassembly of separable bearings

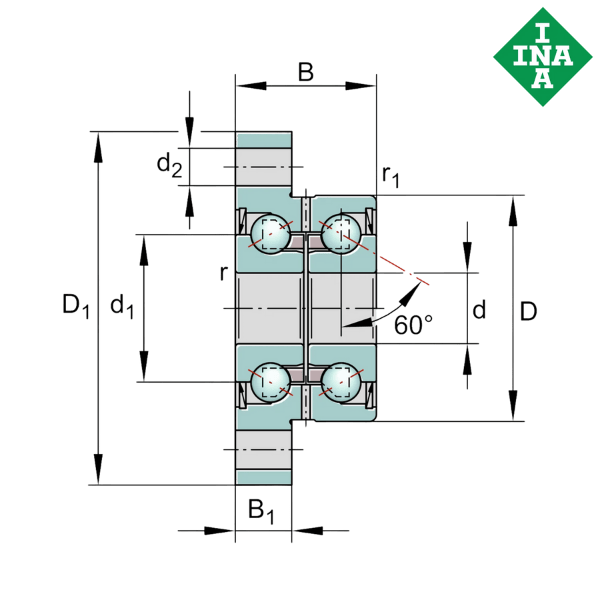

(see Fig. 2):

• Rolling elements

• Inner ring

• Outer ring

Cage Centering Explained:

- Cages centered on rolling elements allow for better lubricant flow into the bearing

- Ring-centered cages offer more precise guidance, which is especially beneficial at high speeds, or in environments with strong vibrations or dynamic forces.

Types of Bearing Cages:

1. Stamped Metal Cages(Fig. 3)

Made from sheet steel or occasionally brass, these cages are:

• Lightweight

• Capable of withstanding high temperatures

• Ideal for standard industrial applications

2. Machined Metal Cages(Fig. 4)

Crafted from brass, steel, or light alloys, these are best suited for:

• High-speed applications

• Elevated temperatures

• Heavy accelerations and vibrations

Their robust design provides durability in demanding settings.

3. Polymer Cages(Fig. 5)

Manufactured from advanced polymers like PA66, PA46, or PEEK, these offer:

• Excellent sliding properties

• Low friction, enabling higher speeds

• Resilience under poor lubrication

• Ability to run for short periods with minimal

lubrication, reducing seizure risk They are especially useful in clean or dry environments where lubrication may be inconsistent

4. Pin-Type Cages(Fig. 6)

Used in large roller bearings, these cages:

• Are made from steel

• Require pierced rollers

• Are lightweight and allow for a high roller count

They’re specialized for heavy-duty applications where a high load capacity is needed.

Conclusion :

Bearing cages are essential for maintaining the performance and longevity of rolling bearings. From guiding rolling elements to improving lubricant flow and enabling higher speeds, the cage design can make or break a bearing’s effectiveness.

By choosing the right cage type and material, you can ensure optimal performance across a wide range of operating conditions—from high-speed machinery to heavy industrial equipment. To know more about Rolling Bearings visit here