Optibelt – Superlative Belt Technology

Let’s talk about belts. And no, we don’t mean the accessories one or the one you wear around your waist. We’re talking about Industrial belts, also known as pulley belts or engine belts. The flexible rubber bands that loop over pulleys to link rotating shafts, transmit power and track movement.

Talking about power transmission, a belt is the cheapest way. It’s a noose of flexible substance used to link two or more rotating shafts mechanically, generally in a parallel form. These belts could also be used as a source of motion as it transmits power more profoundly.

What types of belts are are mainly used?

Timing Belt

The timing belt is also known as the cam belt. It’s a toothed belt that connects the crankshaft to the camshaft and keeps them rotating in sync.

The moveable parts inside any given engine can have little clearance between them, so the most important thing is to keep their timing regular so that they don’t collide. If the timing belt breaks it can cause serious damage to your engine, valves and pistons, and can thus leave you with a heavy repair bill.

Drive Belt

The Drive belt is additionally referred to as serpentine belt

The drive belt or as some of you may call it v-belt in older vehicles, and it derives its name from its ability to weave and wrap itself around various pulleys like a spiral rope. You can identify due to its long ribbing on one side.

Drive belts and v-belts were traditionally a series of belts that came off the crankshaft and were connected to their own accessory group. Drive belts now replace these in newer vehicles. A drive belt is thicker and unifies all the accessories your engine runs, in a belt system. It connects power between accessories such as power steering, alternator, water pump, fan and the air-conditioning compressor.

Why is it important to check and maintain belts?

Like all moving parts on your vehicles and machines, belts degenerate over time and require regular checks and maintenance to ensure their reliability.

A timing belt is virtually impossible to ‘check’ for wear and tear because it is not easily accessible and is usually hidden behind the timing cover. Also, it’s extremely difficult to visually determine if it requires replacing. So, it’s best to check the service history as well as the manufacturer’s handbook and replace it at the scheduled intervals.

A serpentine belt is easier to check as it’s easier to seek. Make sure to check for cracks, splits and tension, not only that but also look at the depths of the ribbing to ensure they are not worn.

Squealing or speaking can indicate a deteriorating or slipped drive belt. Loss of accessory function such as air-conditioning can also be a sign your serpentine belt has failed.

How long do belts last?

It’s always best to see the manufacturer’s guidelines as every machine in which it is to be used is different.

Timing belts typically need to be replaced every 60,000km – 85,000km but should be replaced every seven years even if you haven’t kept a track of the kilometers because rubber can deteriorate over time. Serpentine belts should be replaced at approximately 140,000kms.

Remember that environmental damage – oil dripping onto the belt, driving style, misalignment of pulleys, and the quality of materials used to make the belt can have an impact on its lifespan.

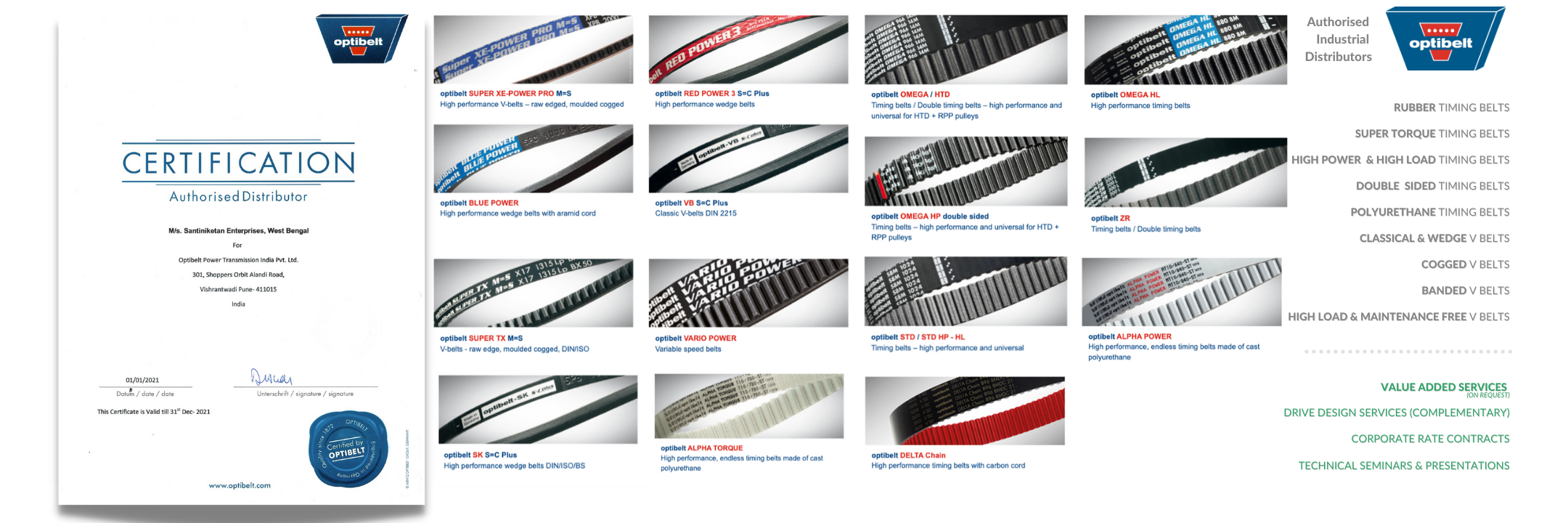

What is Optibelt and why do we recommend it?

Optibelt is an award-winning, fifth-generation German manufacturing company that is a worldwide leader within the manufacture of high-performance belt drives.

At Santiniketan Enterprises, we keep ready stock and recommend Optibelt because of the High-end technology they use to deliver high-quality products.

Optibelt is also the world’s first ribbed belt with an integrated change indicator making it even easier to understand when your belt requires replacing.

Some of the other Optibelt advantages include:

- High-efficiency products

- High-temperature resistance thanks to EPDM rubber

- Service life meets original manufacturer specifications

- Extreme tensile strength

- Quality matched to the specific drive

Who are we?

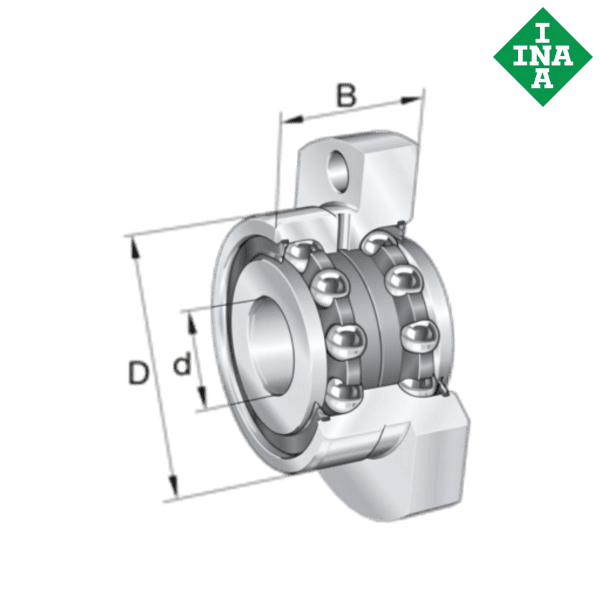

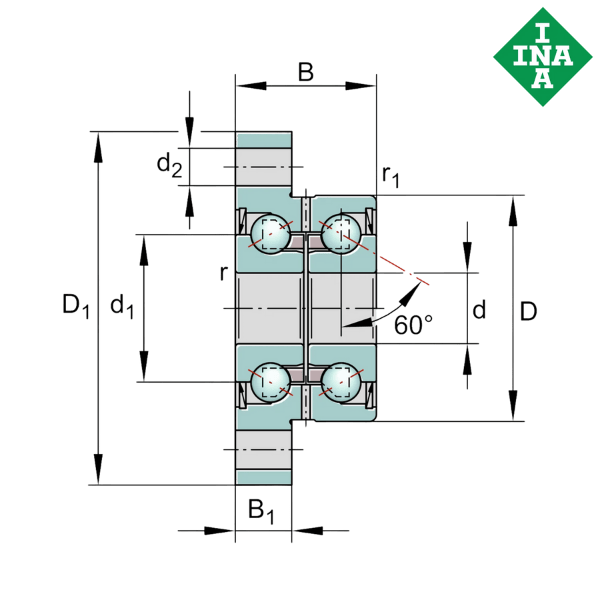

We are an Authorized group of Optibelt and other industrial bearings, belts, pulleys, pumps Distributors in India. Our Extensive understanding of product lines provide support to our customers through economical, selecting the right product and high operative effectiveness. We are known across various locations for being the foremost cost-effective, genuine and timely solution provider for all your industrial needs.

We at Santiniketan Enterprises are committed to serve global markets in Asia and the Middle East with 25+ global brands, and over 10,000 unique SKUs. You can rely on us for a fast, convenient and penny-wise delivery of your goods.