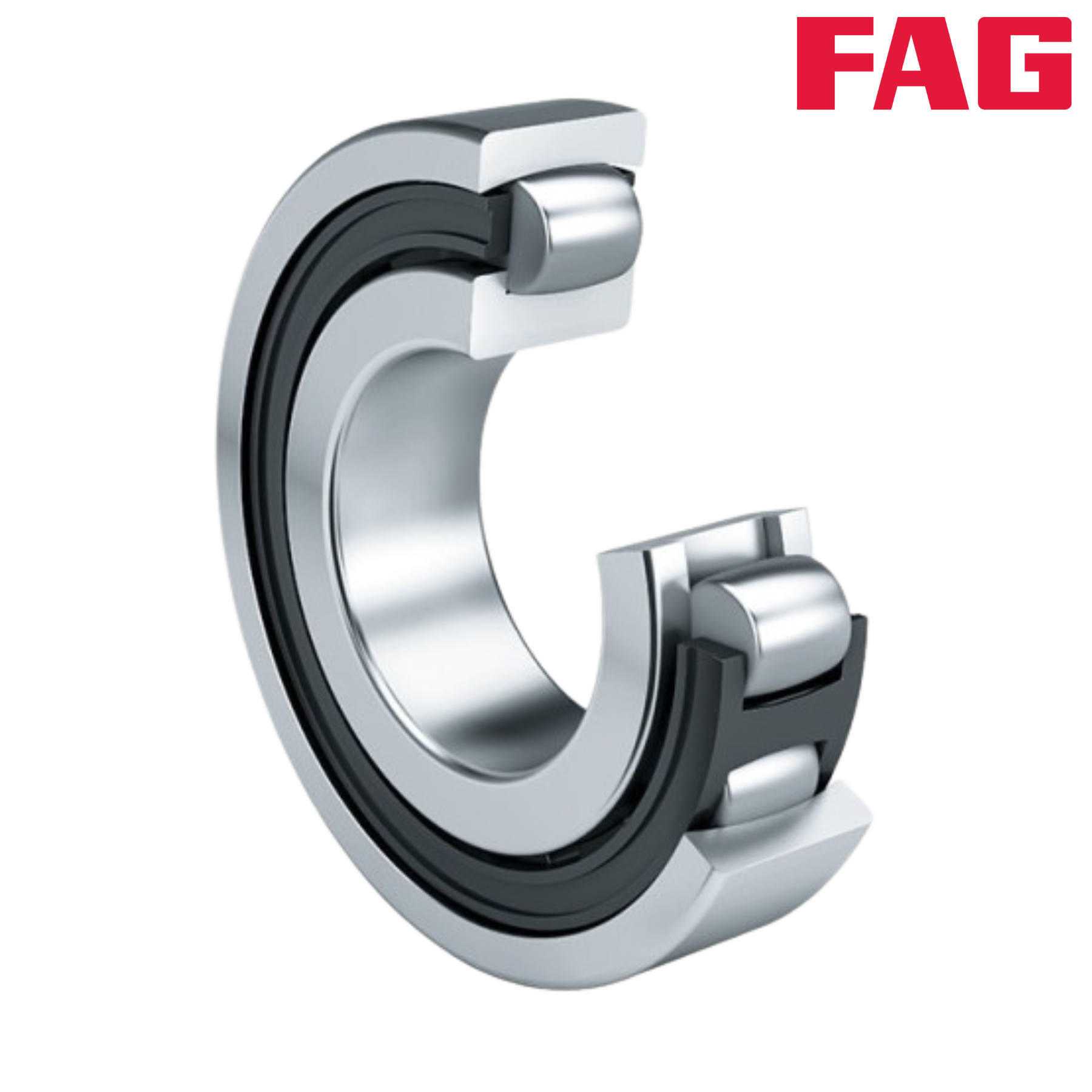

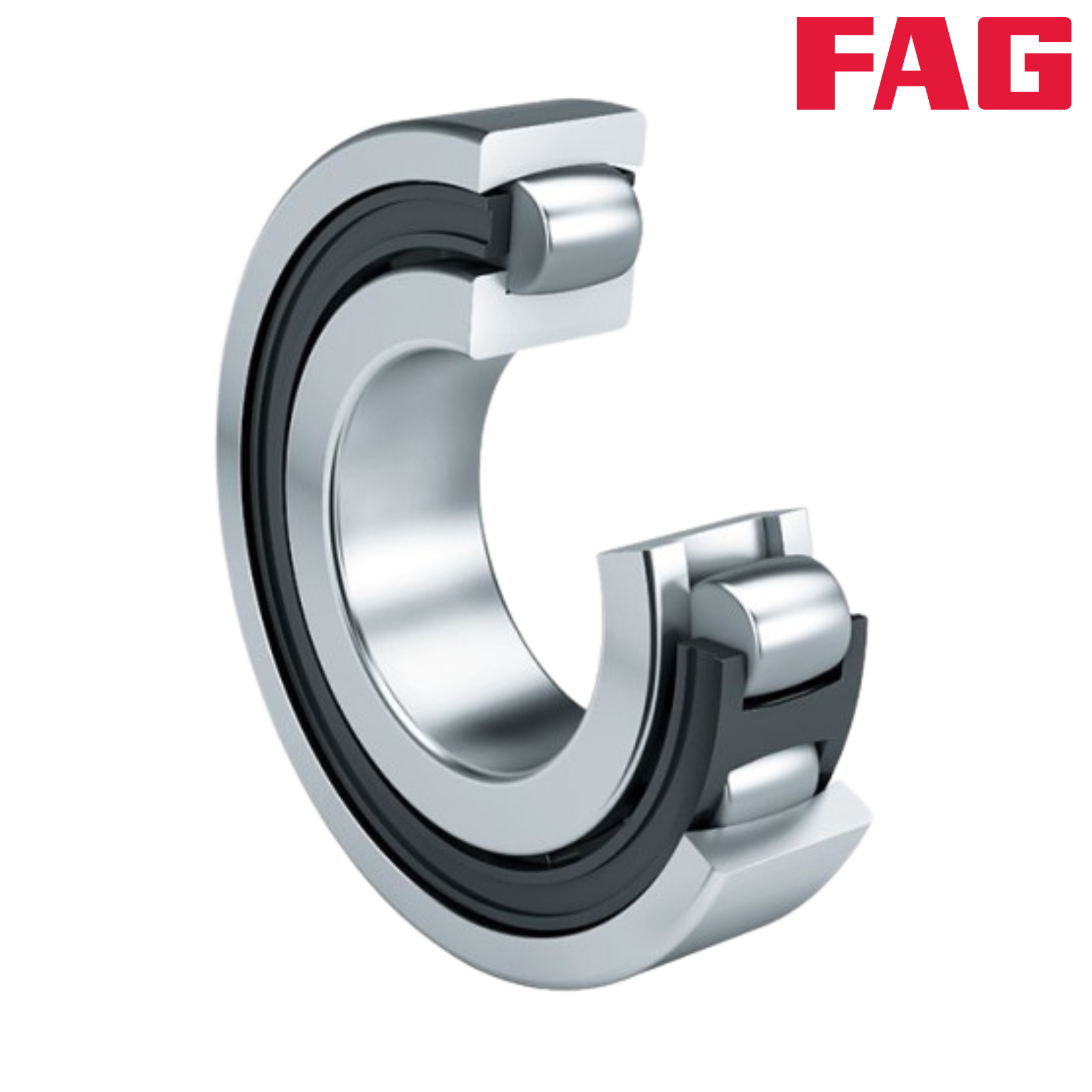

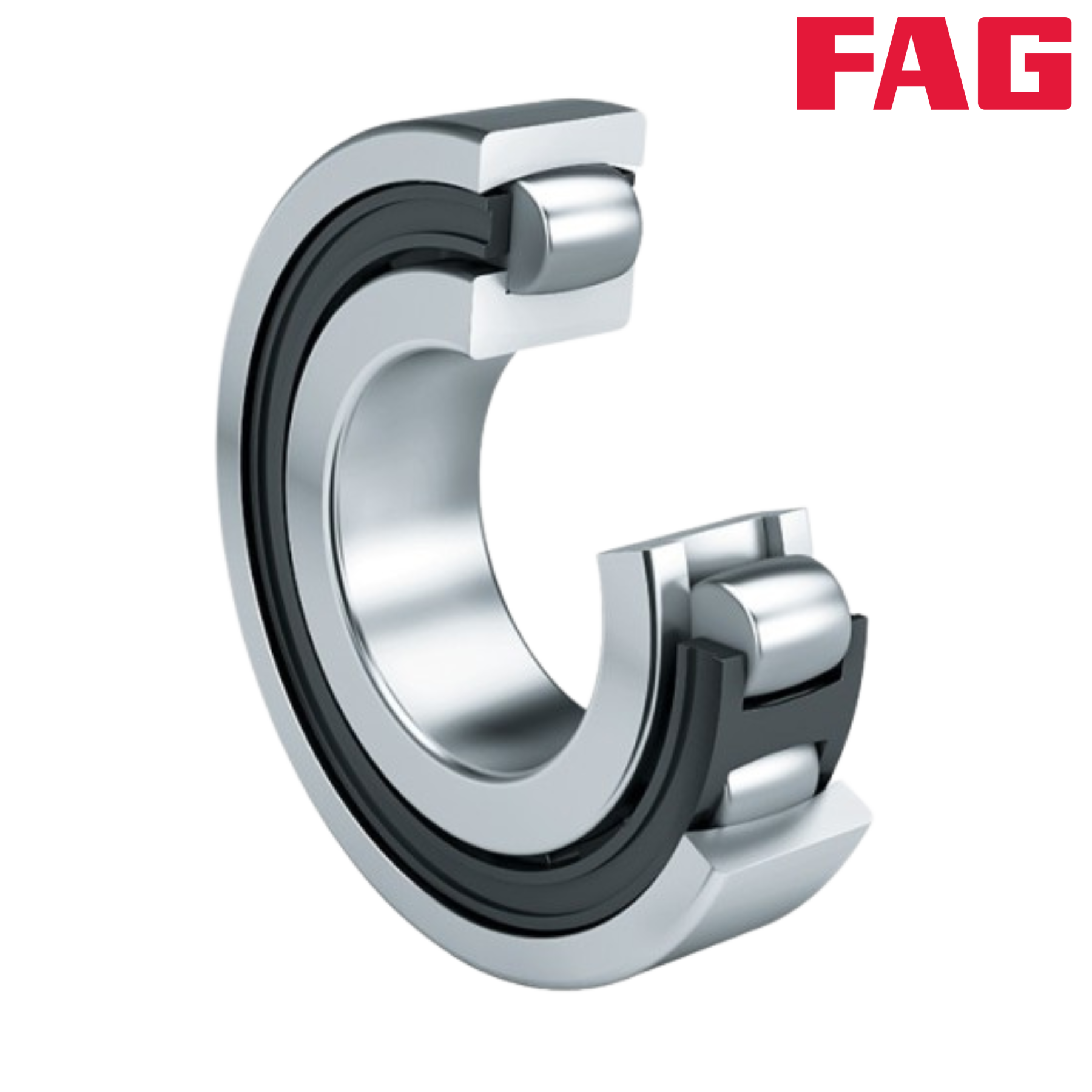

FAG barrel roller bearings are a specific type of spherical roller bearing designed to accommodate high radial loads and misalignment. They have a barrel-shaped outer ring raceway and two rows of barrel-shaped rollers arranged symmetrically along the inner ring raceway. This unique design allows the bearing to compensate for shaft deflections and misalignments, making them suitable for applications where shaft deflection or misalignment is present.

Here are some key features and benefits of FAG barrel roller bearings:

-

High Load Capacity: Barrel roller bearings can accommodate high radial loads and axial loads in both directions due to their symmetrical design and large contact area between the rollers and raceways.

-

Misalignment Compensation: The barrel-shaped rollers and raceways allow the bearing to accommodate shaft misalignment and deflection, reducing stress on the bearing and prolonging its service life.

-

Self-Aligning: Barrel roller bearings are self-aligning, meaning they can automatically adjust to misalignments between the shaft and housing without causing excessive friction or wear.

-

Robust Construction: FAG barrel roller bearings are made of high-quality materials and undergo rigorous manufacturing processes to ensure durability and reliability in demanding applications.

-

Variety of Designs: FAG offers a variety of barrel roller bearing designs, including single row, double row, and split designs, to meet different application requirements and operating conditions.

-

Sealing Options: Barrel roller bearings are available with various sealing options to provide protection against contaminants and moisture ingress, ensuring reliable performance in harsh environments.

-

Easy Installation and Maintenance: Barrel roller bearings are designed for easy installation and maintenance, with standardized dimensions and mounting features that simplify assembly and disassembly procedures.

FAG barrel roller bearings are commonly used in various industries, including mining, construction, paper mills, and steel mills, where heavy radial loads, misalignment, and high speeds are encountered. Their robust construction, self-aligning capability, and high load capacity make them an ideal choice for demanding applications where reliability and performance are essential.