Description

Brand - RINGSPANN

Part Number - FXN 76 - 25/115 NX RINGSPANN

Category - Internal Freewheels FXN

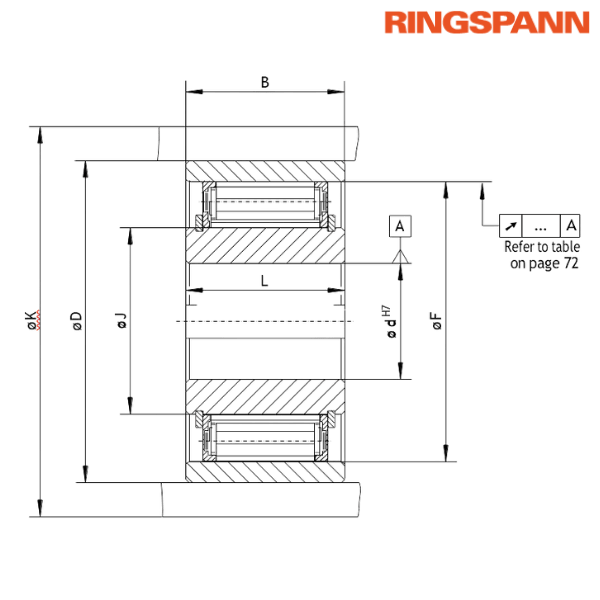

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 50 mm

Maximum Bore Diameter (d) - 60* mm

Dimension (B) - 40 mm

Dimension (D) - 115 P6 mm

Dimension (F) - 100 mm

Dimension (J) - 76 mm

Minimum Dimension (K) - 140 mm

Dimension (L) - 35 mm

Weight - 1.7 kg

Theoretical nominal torque (A) - 1200 Nm

Nominal Torque at Existing Run Out [0.1] T.I.R. (A) - 1170 Nm

Nominal Torque at Existing Run Out [0.2] T.I.R. (A) - 1140 Nm

Nominal Torque at Existing Run Out [0.3] T.I.R. (A) - 1110 Nm

Sprag Lift-off at Inner Ring Speed - 670 RPM

Maximum Speed of Inner Ring Freewheels/ Overruns - 5000 RPM

Maximum Speed of Outer Ring Drives - 268 RPM

Other salient points to be noted:

* Keyway according to DIN 6885

The maximum transmissible torque is 2 times the specified nominal torque

The theoretical nominal torque applies only for ideal concentricity between the inner and outer ring

Features:

• Sprag freewheels without bearing support, equipped with sprag lift-off X)

• Sprag lift-off X allows wear-free freewheeling when the inner ring rotates at high speeds

• The outer ring is pressed into the customer’s housing, enabling a compact and space-efficient design

• Nominal torque capacity: Up to 20,500 Nm

• Bore sizes: Available up to 130 mm

Application as:

• Backstop (For application as backstop in installations with high speeds in freewheeling operation)

• Overrunning Clutch (For application as overrunning clutch in instal- lations with low speeds in driving operation)

Mounting:

• Concentric alignment of the inner and outer rings must be ensured by the customer

• The permissible run out (T.I.R.) must be strictly followed for proper functioning

• Torque is transmitted via press fit on the outer ring

• The outer ring must be installed in a housing with external diameter K as per specification

• Housing material must be steel or grey cast iron (minimum grade GG-20)

• For other materials or smaller diameters, consult the manufacturer regarding torque capacity

• Shaft tolerance must be ISO h6 or j6

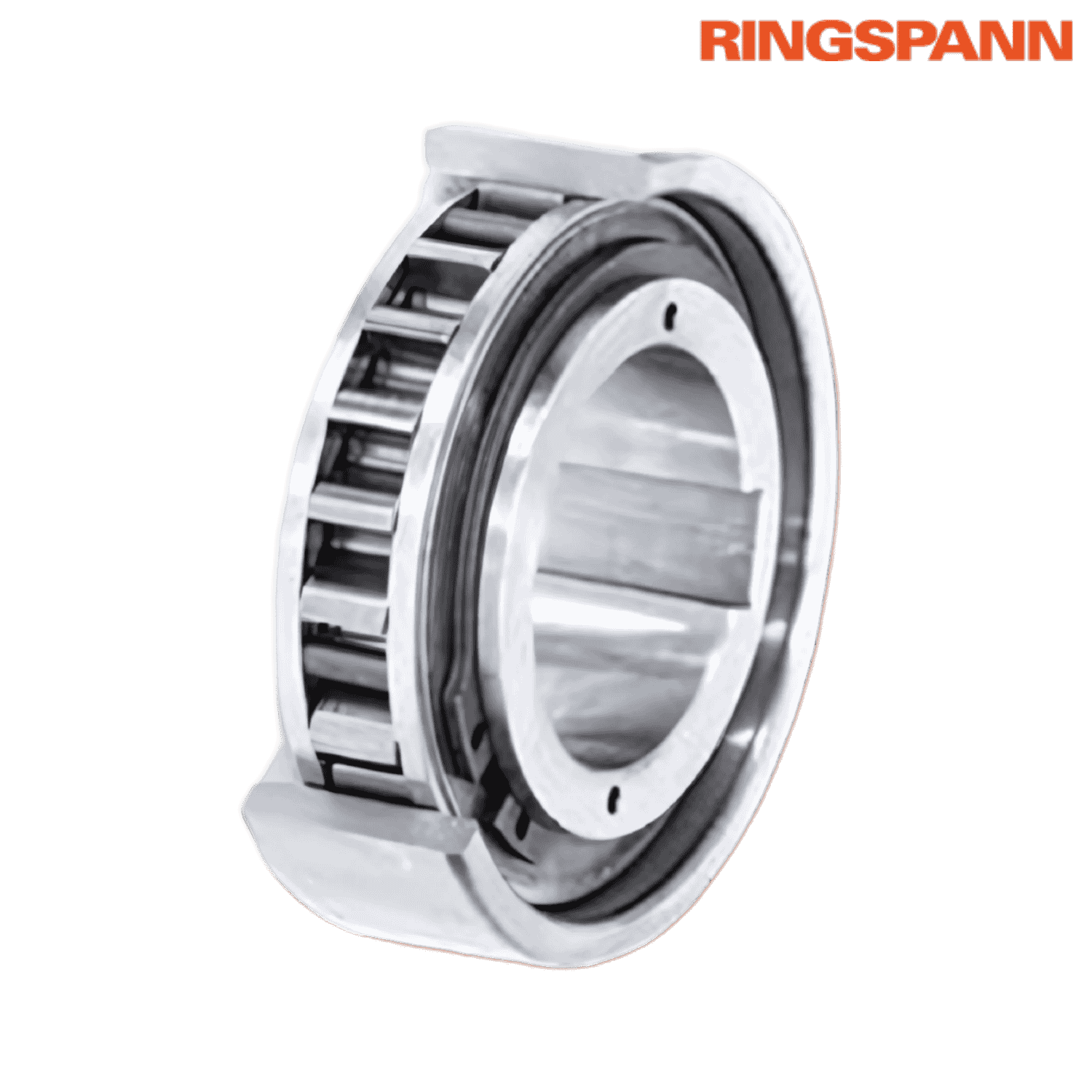

♦ ♦ Images are for representation purposes only

Part Number - FXN 76 - 25/115 NX RINGSPANN

Category - Internal Freewheels FXN

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 50 mm

Maximum Bore Diameter (d) - 60* mm

Dimension (B) - 40 mm

Dimension (D) - 115 P6 mm

Dimension (F) - 100 mm

Dimension (J) - 76 mm

Minimum Dimension (K) - 140 mm

Dimension (L) - 35 mm

Weight - 1.7 kg

Theoretical nominal torque (A) - 1200 Nm

Nominal Torque at Existing Run Out [0.1] T.I.R. (A) - 1170 Nm

Nominal Torque at Existing Run Out [0.2] T.I.R. (A) - 1140 Nm

Nominal Torque at Existing Run Out [0.3] T.I.R. (A) - 1110 Nm

Sprag Lift-off at Inner Ring Speed - 670 RPM

Maximum Speed of Inner Ring Freewheels/ Overruns - 5000 RPM

Maximum Speed of Outer Ring Drives - 268 RPM

Other salient points to be noted:

* Keyway according to DIN 6885

The maximum transmissible torque is 2 times the specified nominal torque

The theoretical nominal torque applies only for ideal concentricity between the inner and outer ring

Features:

• Sprag freewheels without bearing support, equipped with sprag lift-off X)

• Sprag lift-off X allows wear-free freewheeling when the inner ring rotates at high speeds

• The outer ring is pressed into the customer’s housing, enabling a compact and space-efficient design

• Nominal torque capacity: Up to 20,500 Nm

• Bore sizes: Available up to 130 mm

Application as:

• Backstop (For application as backstop in installations with high speeds in freewheeling operation)

• Overrunning Clutch (For application as overrunning clutch in instal- lations with low speeds in driving operation)

Mounting:

• Concentric alignment of the inner and outer rings must be ensured by the customer

• The permissible run out (T.I.R.) must be strictly followed for proper functioning

• Torque is transmitted via press fit on the outer ring

• The outer ring must be installed in a housing with external diameter K as per specification

• Housing material must be steel or grey cast iron (minimum grade GG-20)

• For other materials or smaller diameters, consult the manufacturer regarding torque capacity

• Shaft tolerance must be ISO h6 or j6

♦ ♦ Images are for representation purposes only