Description

Brand - RINGSPANN

Part Number - FXM 46 - 25 NX RINGSPANN

Category - Integrated Freewheels FXM...NX

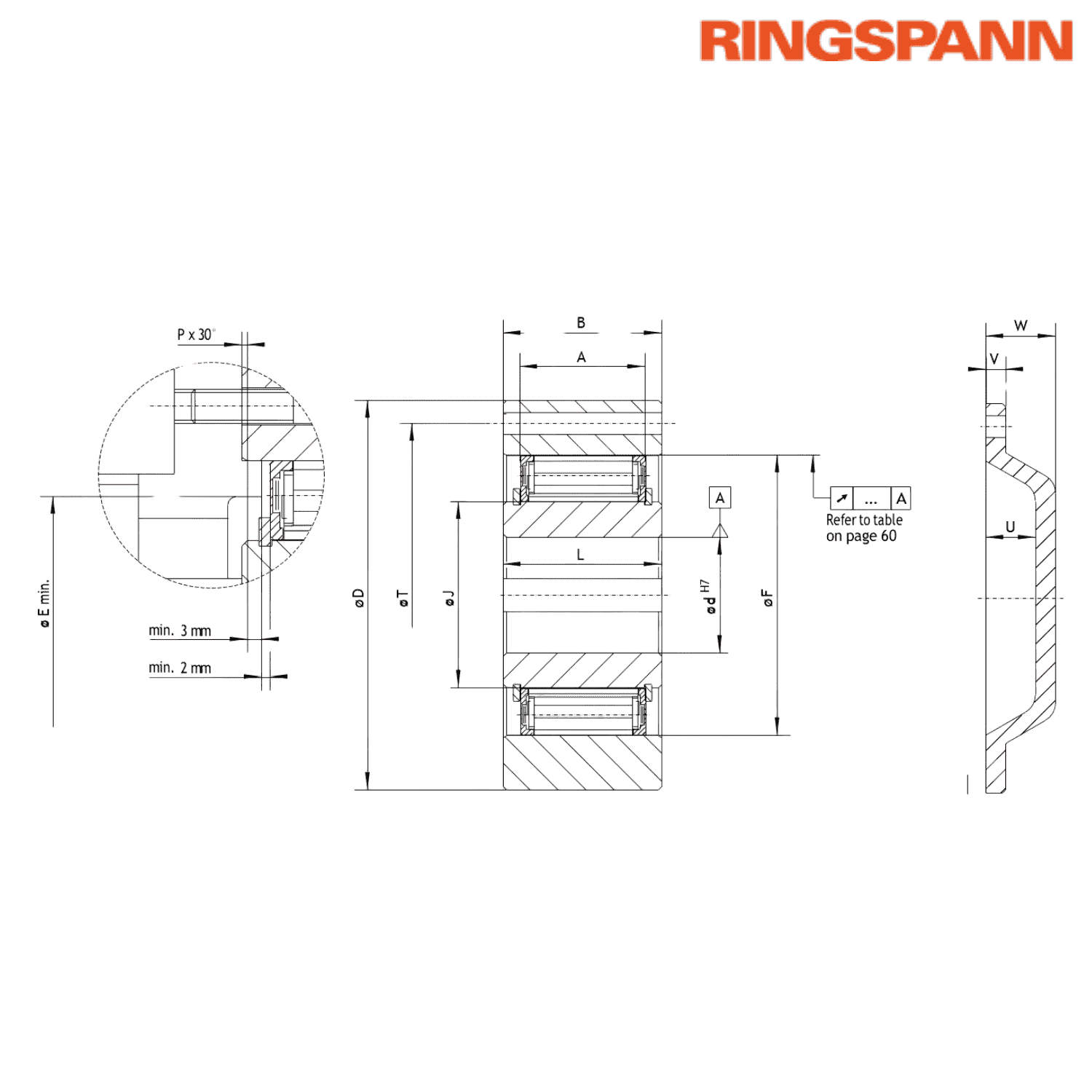

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 30 mm

Maximum Bore Diameter (d) - 30 mm

Dimension (A) - 25 mm

Dimension (B) - 35 mm

Dimension (D) - 95 mm

Minimum Dimension (E) - 56 mm

Dimension (F) - 70 mm

Thread (G) ** - M 6

Dimension (J) - 46 mm

Dimension (L) - 35 mm

Dimension (P) - 1 mm

Dimension (T) - 82 mm

Dimension (U) - 15 mm

Dimension (V) - 6 mm

Dimension (W) - 21 mm

Number of Fastening Holes (Z) ** - 6

Weight - 1.3 kg

Theoretical Nominal Torque (A) - 460 Nm

Nominal Torque at Existing Run Out [0.1] T.I.R. (A) - 450 Nm

Nominal Torque at Existing Run Out [0.2] T.I.R. (A) - 440 Nm

Nominal Torque at Existing Run Out [0.3] T.I.R. (A) - 430 Nm

Sprag Lift-off at Inner Ring Speed - 820 RPM

Maximum Speed of Inner Ring Freewheels/ Overruns - 5000 RPM

Maximum Speed of Outer Ring Drives - 328 RPM

Other salient points to be noted:

• The maximum transmissible torque is 2 times the specified nominal torque

• The theoretical nominal torque applies only for ideal concentricity between the inner and outer ring

• The concentricity is affected by the bearing play and centering errors of the neighbouring parts

• Then the nominal torques specified in the table apply, whilst taking into consideration the existing run out (T.I.R.)

• Higher speeds upon request

* Keyway according to DIN 6885

** Z = Number of fastening holes for screws G on pitch circle T

Features:

• Integrated Freewheels FXM are sprag freewheels supplied without bearing support, equipped with sprag lift-off X

• The sprag lift-off X feature ensures wear-free freewheeling when the inner ring operates at high rotational speeds

• Capable of handling nominal torques up to 1,230,000 Nm

• Available with bores up to 500 mm

Application as:

• Backstop (Suitable for use as a backstop in installations where the freewheeling operation occurs at high speeds)

• Overrunning Clutch (Suitable for use as an overrunning clutch in installations where the driving operation takes place at low speeds)

Mounting:

• Integrated Freewheels FXM are supplied without bearing support

• The customer must ensure concentric alignment of both the inner ring and outer ring

• The permissible runout (T.I.R.) must be carefully observed

• The Integrated Freewheel FXM is centered via the outer track F on the customer’s attachment part

• The pilot diameter of the attachment part must have a tolerance of ISO h6 or h7

• The shaft tolerance must comply with ISO h6 or j6

Lubrication:

• When operating at speeds above the sprag lift-off speed, no special lubrication is required; the freewheel operates in a maintenance-free manner

• When operating at speeds below the sprag lift-off speed, an oil lubrication of the specified quality must be provided to ensure proper performance

♦ ♦ Images are for representation purposes only