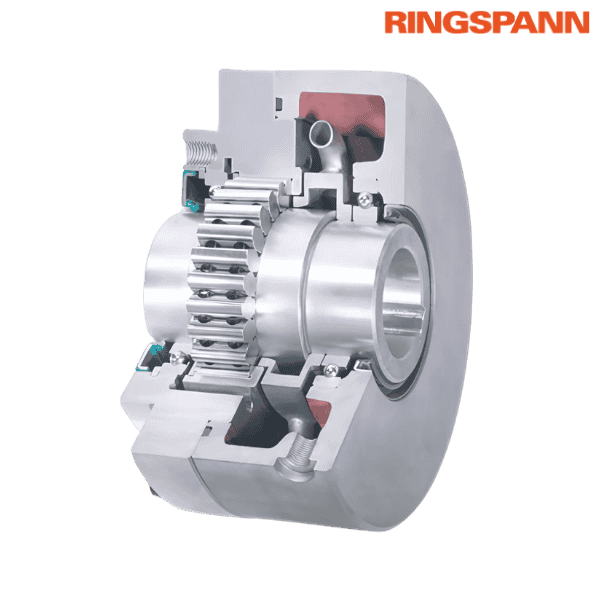

Description

Brand - RINGSPANN

Part Number - FKh 24 ATR RINGSPANN

Category - Complete Freewheels FKh

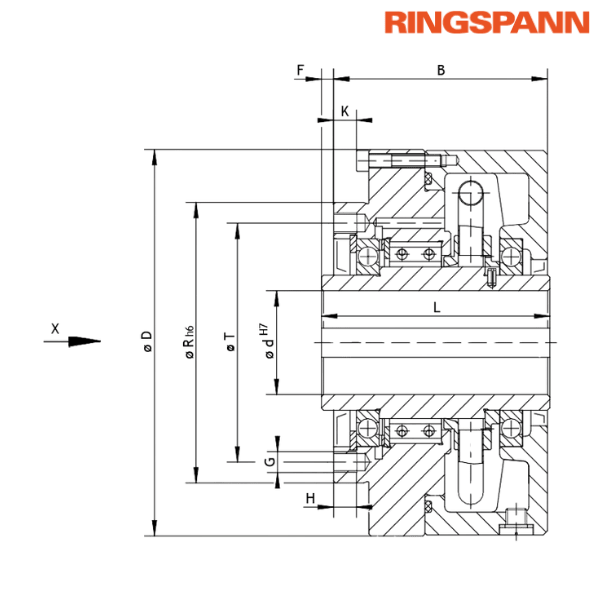

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 35 mm

Maximum Bore Diameter (d) * - 40 mm

Dimension (B) - 90 mm

Dimension (D) - 170 mm

Dimension (F) - 1 mm

Thread (G) ** - M10

Dimension (H) - 11 mm

Dimension (K) - 9 mm

Dimension (L) - 95 mm

Dimension (R) - 135 mm

Dimension (T) - 115 mm

Number of tapped holes (Z) ** - 6

Weight - 9.6 kg

Type - Type with Hydrodynamic Sprag Lift-off for Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Nominal Torque (MN) - 1100 Nm

Maximum Speed of Outer Ring Overruns - 3000 RPM

Maximum Speed of Inner Ring Drives - 3000 RPM

Description of Suffix:

ATR - Type with Hydrodynamic Sprag Lift-off for Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of tapped holes G on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

• Complete Freewheels FKh with hydrodynamic sprag lift-off are ideal for systems where an assembly is driven by two or more motors or turbines operating at the same or similar high speed.

• These are sealed sprag freewheels equipped with ball bearings

• Supplied pre-filled with oil and ready for installation; biodegradable oil available upon request

• Designed to handle nominal torques up to 14,000 Nm

• Available with bore sizes up to 95 mm

Application as: Overrunning Clutch (At high speeds, the rotational speed during freewheeling and driving operation is either identical or very similar)

Application Example:

• Two Complete Freewheels FKh 28 ATR are used as overrunning clutches in a fan drive system

• The fan is powered either by an electric motor or a turbine

• This system eliminates the need for actuated clutches, avoiding the need for manual or automatic switching between drives

• The hydrodynamic sprag lift-off feature ensures wear-free freewheeling operation, especially when driving and freewheeling speeds are equal or similar

Mounting:

• The customer attachment part must be centered on diameter R and then bolted onto the face of the freewheel

• The outer ring should rotate freely during freewheeling operation

• Shaft tolerance must be ISO h6 or j6

• Pilot diameter R of the attachment part must be ISO H7 or J7

♦ ♦ Images are for representation purposes only

Part Number - FKh 24 ATR RINGSPANN

Category - Complete Freewheels FKh

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 35 mm

Maximum Bore Diameter (d) * - 40 mm

Dimension (B) - 90 mm

Dimension (D) - 170 mm

Dimension (F) - 1 mm

Thread (G) ** - M10

Dimension (H) - 11 mm

Dimension (K) - 9 mm

Dimension (L) - 95 mm

Dimension (R) - 135 mm

Dimension (T) - 115 mm

Number of tapped holes (Z) ** - 6

Weight - 9.6 kg

Type - Type with Hydrodynamic Sprag Lift-off for Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Nominal Torque (MN) - 1100 Nm

Maximum Speed of Outer Ring Overruns - 3000 RPM

Maximum Speed of Inner Ring Drives - 3000 RPM

Description of Suffix:

ATR - Type with Hydrodynamic Sprag Lift-off for Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of tapped holes G on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

• Complete Freewheels FKh with hydrodynamic sprag lift-off are ideal for systems where an assembly is driven by two or more motors or turbines operating at the same or similar high speed.

• These are sealed sprag freewheels equipped with ball bearings

• Supplied pre-filled with oil and ready for installation; biodegradable oil available upon request

• Designed to handle nominal torques up to 14,000 Nm

• Available with bore sizes up to 95 mm

Application as: Overrunning Clutch (At high speeds, the rotational speed during freewheeling and driving operation is either identical or very similar)

Application Example:

• Two Complete Freewheels FKh 28 ATR are used as overrunning clutches in a fan drive system

• The fan is powered either by an electric motor or a turbine

• This system eliminates the need for actuated clutches, avoiding the need for manual or automatic switching between drives

• The hydrodynamic sprag lift-off feature ensures wear-free freewheeling operation, especially when driving and freewheeling speeds are equal or similar

Mounting:

• The customer attachment part must be centered on diameter R and then bolted onto the face of the freewheel

• The outer ring should rotate freely during freewheeling operation

• Shaft tolerance must be ISO h6 or j6

• Pilot diameter R of the attachment part must be ISO H7 or J7

♦ ♦ Images are for representation purposes only