Description

Brand - RINGSPANN

Part Number - FBL 44 SF RINGSPANN

Category - Complete Freewheels FBL

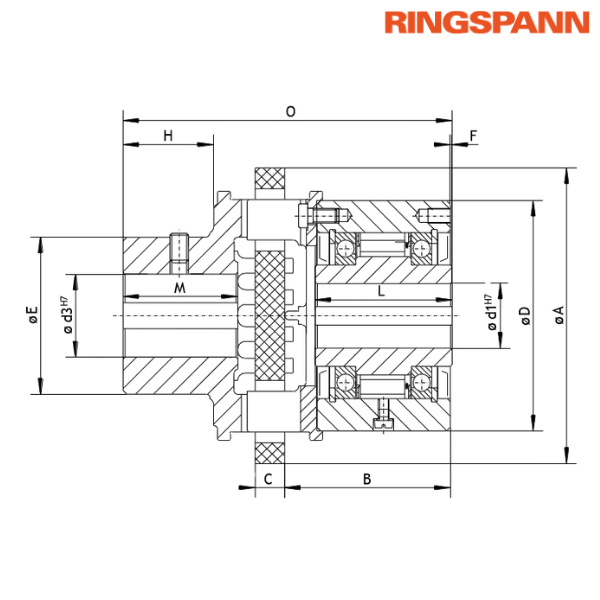

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d1)* - 25 mm

Maximum Bore Diameter (d1) * - 25 mm

Standard Bore Diameter (d3) - 25 mm

Minimum Bore Diameter (d3) - 20 mm

Maximum Bore Diameter (d3) - 42 mm

Dimension (A) - 135 mm

Dimension (B) - 65 mm

Dimension (C) - 14 mm

Dimension (D) - 90 mm

Dimension (E) - 66 mm

Dimension (F) - 0.5 mm

Dimension (H) - 41 mm

Dimension (L) - 50 mm

Dimension (M) - 53 mm

Dimension (O) - 140 mm

Weight - 4.6 kg

Type - Standard Type for Universal Use (SF)

Nominal Torque (MN) - 190 Nm

Maximum Speed of Inner Ring Overruns - 1900 RPM

Maximum Speed of Outer Ring Overruns - 2200 RPM

Description of Suffix:

SF - Standard Type for Universal Use

Other salient points to be noted:

* Keyway according to DIN 6885

• The maximum transmissible torque is 2 times the specified nominal torque

• For bore d1: Keyway according to DIN 6885

• For bore d1: Keyway width tolerance JS10

• For bore d3: Keyway according to DIN 6885

• For bore d3: Keyway width tolerance P9

Features:

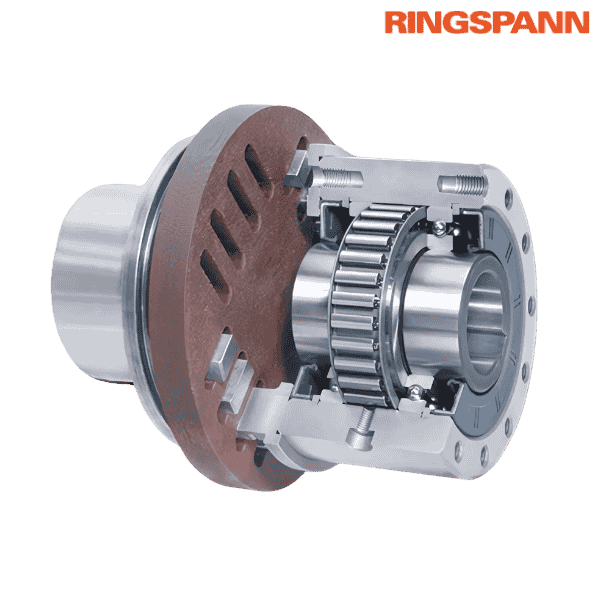

• Complete Freewheels FBL with RINGSPANN Shaft Coupling are sealed sprag freewheels with ball bearings, designed for coupling two shafts

• Capable of handling nominal torques up to 8,000 Nm

• Available with bores up to 140 mm; many standard bore sizes available

• The torsionally stiff RINGSPANN Shaft Coupling can accommodate large radial and angular misalignments without transmitting reactive forces to adjacent bearings

Application as: Overrunning Clutch

Application Example:

• Complete Freewheel FBL 82 SFZ is used as an overrunning clutch in the drive unit of a conveyor belt system with an additional creep drive

• In normal operation (freewheeling mode), the main motor drives the belt, while the outer ring of the freewheel overruns, automatically disengaging the creep drive

• Since high speed freewheeling is involved, a sprag lift-off type Z is used, ensuring contact-free, wear-free operation of the sprags

Mounting:

• The flexible disk of the shaft coupling must remain axially free after installation to prevent distortion of the ball bearings in the freewheel due to thermal expansion

• The shaft coupling can be mounted on either the right or left side of the freewheel, based on the required freewheeling direction

• The shaft tolerance must conform to ISO h6 or j6

♦ ♦ Images are for representation purposes only

Part Number - FBL 44 SF RINGSPANN

Category - Complete Freewheels FBL

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d1)* - 25 mm

Maximum Bore Diameter (d1) * - 25 mm

Standard Bore Diameter (d3) - 25 mm

Minimum Bore Diameter (d3) - 20 mm

Maximum Bore Diameter (d3) - 42 mm

Dimension (A) - 135 mm

Dimension (B) - 65 mm

Dimension (C) - 14 mm

Dimension (D) - 90 mm

Dimension (E) - 66 mm

Dimension (F) - 0.5 mm

Dimension (H) - 41 mm

Dimension (L) - 50 mm

Dimension (M) - 53 mm

Dimension (O) - 140 mm

Weight - 4.6 kg

Type - Standard Type for Universal Use (SF)

Nominal Torque (MN) - 190 Nm

Maximum Speed of Inner Ring Overruns - 1900 RPM

Maximum Speed of Outer Ring Overruns - 2200 RPM

Description of Suffix:

SF - Standard Type for Universal Use

Other salient points to be noted:

* Keyway according to DIN 6885

• The maximum transmissible torque is 2 times the specified nominal torque

• For bore d1: Keyway according to DIN 6885

• For bore d1: Keyway width tolerance JS10

• For bore d3: Keyway according to DIN 6885

• For bore d3: Keyway width tolerance P9

Features:

• Complete Freewheels FBL with RINGSPANN Shaft Coupling are sealed sprag freewheels with ball bearings, designed for coupling two shafts

• Capable of handling nominal torques up to 8,000 Nm

• Available with bores up to 140 mm; many standard bore sizes available

• The torsionally stiff RINGSPANN Shaft Coupling can accommodate large radial and angular misalignments without transmitting reactive forces to adjacent bearings

Application as: Overrunning Clutch

Application Example:

• Complete Freewheel FBL 82 SFZ is used as an overrunning clutch in the drive unit of a conveyor belt system with an additional creep drive

• In normal operation (freewheeling mode), the main motor drives the belt, while the outer ring of the freewheel overruns, automatically disengaging the creep drive

• Since high speed freewheeling is involved, a sprag lift-off type Z is used, ensuring contact-free, wear-free operation of the sprags

Mounting:

• The flexible disk of the shaft coupling must remain axially free after installation to prevent distortion of the ball bearings in the freewheel due to thermal expansion

• The shaft coupling can be mounted on either the right or left side of the freewheel, based on the required freewheeling direction

• The shaft tolerance must conform to ISO h6 or j6

♦ ♦ Images are for representation purposes only