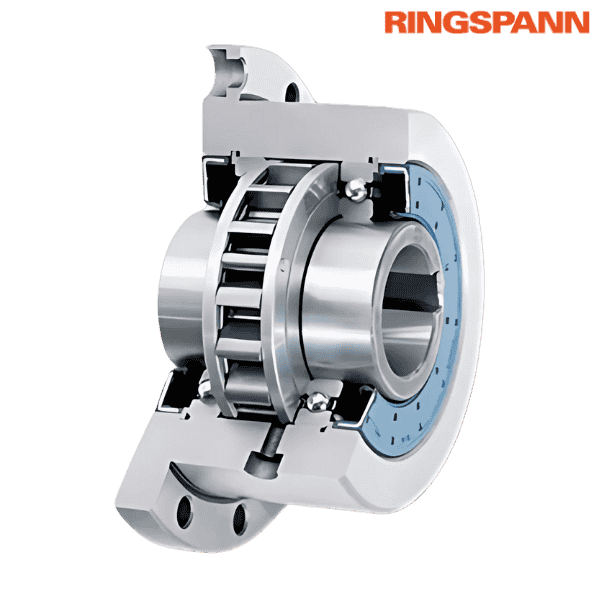

Description

Brand - RINGSPANN

Part Number - FBF 200 SX RINGSPANN

Category - Complete Freewheels FBF

Principal Dimensions & Specifications (Metric):

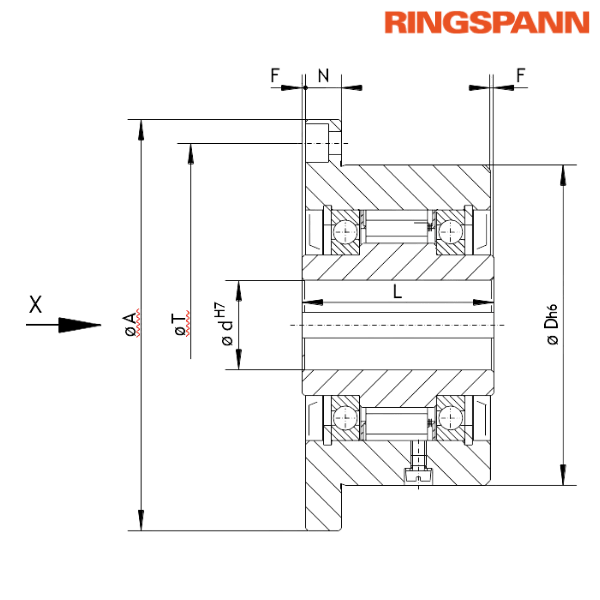

Standard Bore Diameter (d) - 120 mm

Maximum Bore Diameter (d) - 120 mm

Dimension (A) - 370 mm

Dimension (D) - 300 mm

Dimension (F) - 5 mm

Thread (G) ** - M16

Dimension (L) - 160 mm

Dimension (N) - 25 mm

Dimension (T) - 335 mm

Number of Fastening Holes (Z) ** - 16

Weight - 68 kg

Type - Type with Sprag Lift-off X For Extended Service Life using Sprag Lift-off at High Speed Rotating Inner Ring (SX)

Nominal Torque (MN) - 23000 Nm

Sprag Lift-off at Inner Ring Speed - 240 RPM

Maximum Speed of Inner Ring Freewheels/ Overruns - 630 RPM

Maximum Speed of Outer Ring Drives - 96 RPM

Description of Suffix:

SX - Type with Sprag Lift-off X For Extended Service Life using Sprag Lift-off at High Speed Rotating Inner Ring

Other salient points to be noted:

** Z = Number of fastening holes for screws G (DIN EN ISO 4762) on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

• Complete Freewheels FBF with mounting flange are sealed sprag freewheels integrated with ball bearings

• Capable of handling nominal torques up to 160,000 Nm

• Available with bores up to 300 mm

Application as: Backstop, Overrunning Clutch, Indexing Freewheel

Application Example:

• Complete Freewheel FBF 72 DX is used as an overrunning clutch in a meat processing machine (chopper)

• During the mixing process, a gear motor drives both the bowl (via gear wheel drive) and the knife shaft (via belt drive and locked freewheel)

• During the cutting process, a second motor drives the knife shaft at high speed

• In this phase, the inner ring of the freewheel overruns the outer ring driven by the gear motor, automatically disengaging the gear motor

• To support high-speed freewheeling, a sprag lift-off type X is used, allowing the sprags to operate without contact, ensuring a wear-free freewheeling operation

Mounting:

• The customer’s attachment part is centered on the external diameter (D)

• It is then bolted to the face via the flange

• The shaft tolerance must conform to ISO h6 or j6

• The pilot diameter (D) of the attachment part must comply with ISO H7 or J7

♦ ♦ Images are for representation purposes only

Part Number - FBF 200 SX RINGSPANN

Category - Complete Freewheels FBF

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) - 120 mm

Maximum Bore Diameter (d) - 120 mm

Dimension (A) - 370 mm

Dimension (D) - 300 mm

Dimension (F) - 5 mm

Thread (G) ** - M16

Dimension (L) - 160 mm

Dimension (N) - 25 mm

Dimension (T) - 335 mm

Number of Fastening Holes (Z) ** - 16

Weight - 68 kg

Type - Type with Sprag Lift-off X For Extended Service Life using Sprag Lift-off at High Speed Rotating Inner Ring (SX)

Nominal Torque (MN) - 23000 Nm

Sprag Lift-off at Inner Ring Speed - 240 RPM

Maximum Speed of Inner Ring Freewheels/ Overruns - 630 RPM

Maximum Speed of Outer Ring Drives - 96 RPM

Description of Suffix:

SX - Type with Sprag Lift-off X For Extended Service Life using Sprag Lift-off at High Speed Rotating Inner Ring

Other salient points to be noted:

** Z = Number of fastening holes for screws G (DIN EN ISO 4762) on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

• Complete Freewheels FBF with mounting flange are sealed sprag freewheels integrated with ball bearings

• Capable of handling nominal torques up to 160,000 Nm

• Available with bores up to 300 mm

Application as: Backstop, Overrunning Clutch, Indexing Freewheel

Application Example:

• Complete Freewheel FBF 72 DX is used as an overrunning clutch in a meat processing machine (chopper)

• During the mixing process, a gear motor drives both the bowl (via gear wheel drive) and the knife shaft (via belt drive and locked freewheel)

• During the cutting process, a second motor drives the knife shaft at high speed

• In this phase, the inner ring of the freewheel overruns the outer ring driven by the gear motor, automatically disengaging the gear motor

• To support high-speed freewheeling, a sprag lift-off type X is used, allowing the sprags to operate without contact, ensuring a wear-free freewheeling operation

Mounting:

• The customer’s attachment part is centered on the external diameter (D)

• It is then bolted to the face via the flange

• The shaft tolerance must conform to ISO h6 or j6

• The pilot diameter (D) of the attachment part must comply with ISO H7 or J7

♦ ♦ Images are for representation purposes only