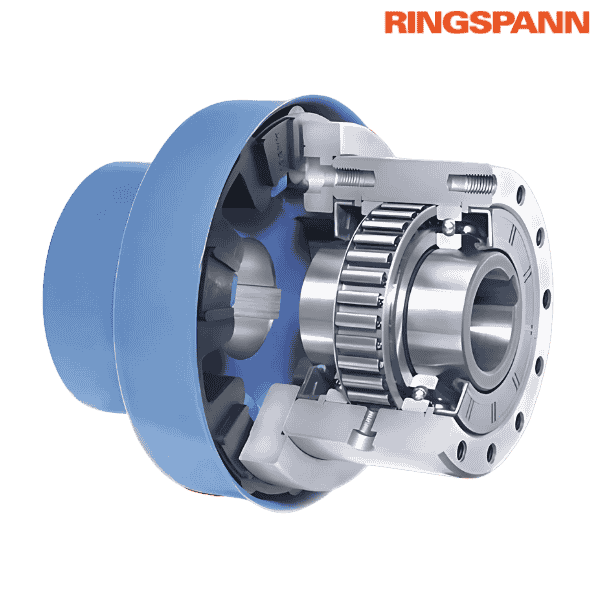

Description

Brand - RINGSPANN

Part Number - FBE 82 SFZ RINGSPANN

Category - Complete Freewheels FBE

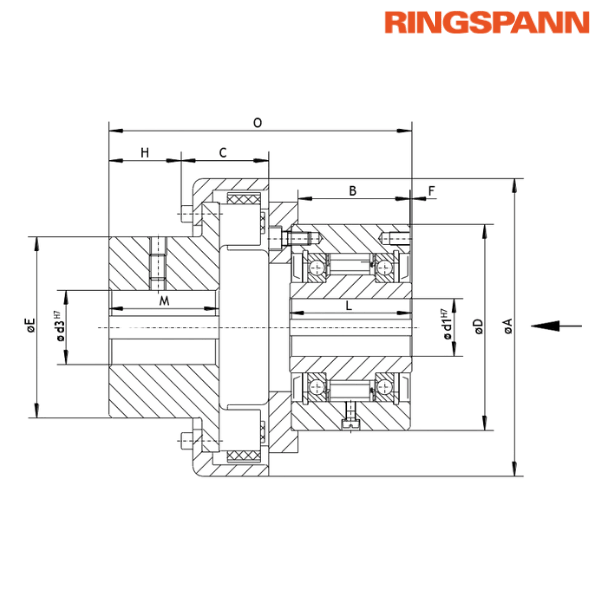

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d1) * - 50 mm

Maximum Bore Diameter (d1) * - 50 mm

Standard Bore Diameter (d3) - 50 mm

Minimum Bore Diameter (d3) - 25 mm

Maximum Bore Diameter (d3) - 75 mm

Dimension (A) - 202 mm

Dimension (B) - 67 mm

Dimension (C) - 64 mm

Dimension (D) - 135 mm

Dimension (E) - 120 mm

Dimension (F) - 2 mm

Dimension (H) - 46 mm

Dimension (L) - 75 mm

Dimension (M) - 75 mm

Dimension (O) - 200 mm

Weight - 1206 kg

Type - Type with Sprag Lift-off Z For Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring (SFZ)

Nominal Torque (MN) - 1700 Nm

Sprag Lift-off at Outer Ring Speed - 1450 RPM

Maximum Speed of Outer Ring Overruns - 1600 RPM

Maximum Speed of Inner Ring Drives - 580 RPM

Description of Suffix:

SFZ - Type with Sprag Lift-off Z For Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Other salient points to be noted:

* Keyway according to DIN 6885

• The maximum transmissible torque is 2 times the specified nominal torque

• For bore d1: Keyway according to DIN 6885

• For bore d1: Keyway width tolerance JS10

• For bore d3: Keyway according to DIN 6885

• For bore d3: Keyway width tolerance P9

Features:

• Complete Freewheels FBE with flexible shaft coupling are sealed sprag freewheels with ball bearings, designed for coupling two aligned shafts

• Handles nominal torques up to 160,000 Nm

• Available with bores up to 300 mm; many standard bore sizes readily available

Application as: Overrunning Clutch

Application Example:

• Two Complete Freewheels FBE 72 with shaft coupling are used as overrunning clutches in the drive unit of a tube mill with an auxiliary drive

• A standard FBE 72 SF (Freewheel 1) is installed between the main drive and the angular gear

• A FBE 72 LZ (Freewheel 2), equipped with sprag lift-off Z, is installed between the auxiliary drive and the angular gear

• In auxiliary power mode, the auxiliary drive powers the system through Freewheel 2 (driving mode), while Freewheel 1 operates in freewheeling mode at low speed

• In main motor mode, the system is powered via Freewheel 1 (driving mode), while Freewheel 2 automatically overruns and disengages the auxiliary drive (freewheeling mode)

• The sprag lift-off Z type in Freewheel 2 allows for contact-free, wear-free operation at high speed during freewheeling

Mounting:

• The shaft coupling can be installed on either the right or left side of the freewheel, depending on the required freewheeling direction

• The shaft tolerance must comply with ISO h6 or j6

♦ ♦ Images are for representation purposes only

Part Number - FBE 82 SFZ RINGSPANN

Category - Complete Freewheels FBE

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d1) * - 50 mm

Maximum Bore Diameter (d1) * - 50 mm

Standard Bore Diameter (d3) - 50 mm

Minimum Bore Diameter (d3) - 25 mm

Maximum Bore Diameter (d3) - 75 mm

Dimension (A) - 202 mm

Dimension (B) - 67 mm

Dimension (C) - 64 mm

Dimension (D) - 135 mm

Dimension (E) - 120 mm

Dimension (F) - 2 mm

Dimension (H) - 46 mm

Dimension (L) - 75 mm

Dimension (M) - 75 mm

Dimension (O) - 200 mm

Weight - 1206 kg

Type - Type with Sprag Lift-off Z For Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring (SFZ)

Nominal Torque (MN) - 1700 Nm

Sprag Lift-off at Outer Ring Speed - 1450 RPM

Maximum Speed of Outer Ring Overruns - 1600 RPM

Maximum Speed of Inner Ring Drives - 580 RPM

Description of Suffix:

SFZ - Type with Sprag Lift-off Z For Extended Service Life Using Sprag Lift-off at High Speed Rotating Outer Ring

Other salient points to be noted:

* Keyway according to DIN 6885

• The maximum transmissible torque is 2 times the specified nominal torque

• For bore d1: Keyway according to DIN 6885

• For bore d1: Keyway width tolerance JS10

• For bore d3: Keyway according to DIN 6885

• For bore d3: Keyway width tolerance P9

Features:

• Complete Freewheels FBE with flexible shaft coupling are sealed sprag freewheels with ball bearings, designed for coupling two aligned shafts

• Handles nominal torques up to 160,000 Nm

• Available with bores up to 300 mm; many standard bore sizes readily available

Application as: Overrunning Clutch

Application Example:

• Two Complete Freewheels FBE 72 with shaft coupling are used as overrunning clutches in the drive unit of a tube mill with an auxiliary drive

• A standard FBE 72 SF (Freewheel 1) is installed between the main drive and the angular gear

• A FBE 72 LZ (Freewheel 2), equipped with sprag lift-off Z, is installed between the auxiliary drive and the angular gear

• In auxiliary power mode, the auxiliary drive powers the system through Freewheel 2 (driving mode), while Freewheel 1 operates in freewheeling mode at low speed

• In main motor mode, the system is powered via Freewheel 1 (driving mode), while Freewheel 2 automatically overruns and disengages the auxiliary drive (freewheeling mode)

• The sprag lift-off Z type in Freewheel 2 allows for contact-free, wear-free operation at high speed during freewheeling

Mounting:

• The shaft coupling can be installed on either the right or left side of the freewheel, depending on the required freewheeling direction

• The shaft tolerance must comply with ISO h6 or j6

♦ ♦ Images are for representation purposes only