Description

Brand - RINGSPANN

Part Number - FB 82 SF RINGSPANN

Category - Complete Freewheels FB

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) * - 50 mm

Maximum Bore Diameter (d) * - 50 mm

Outer Diameter (D) - 135 mm

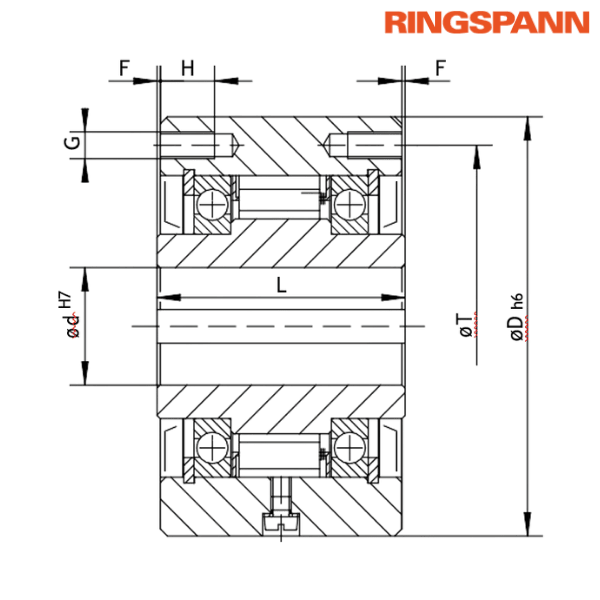

Dimension (F) - 2 mm

Thread (G) ** - M10

Dimension (H) - 16 mm

Dimension (L) - 75 mm

Dimension (T) - 115 mm

Number of Tapped Holes (Z) ** - 12

Weight - 5.8 kg

Type - Standard Type for Universal Use (SF Type)

Nominal Torque (MN) - 1800 Nm

Maximum Speed of Inner Ring Freewheels/ Overruns - 1025 RPM

Maximum Speed of Outer Ring Freewheels/ Overruns - 1450 RPM

Description of Suffix:

SF - Standard Type for Universal Use (SF Type)

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of tapped holes G on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

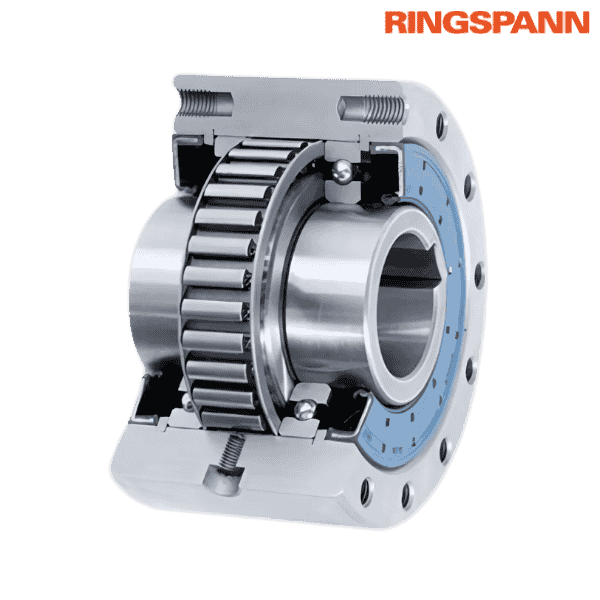

• Type: sealed sprag freewheels with integrated ball bearings

• Lubrication: supplied oil-filled and ready for installation

• Eco Option: Available with biodegradable oil upon request

• Variants: Standard model, three enhanced versions designed for extended service life and reliable performance in demanding applications

• Nominal torque capacity up to 160,000 Nm

• Bore sizes up to 300 mm

• A wide selection of standardized bore diameters is available, ensuring short lead times and fast delivery

Application as: Backstop, Overrunning Clutch, Indexing Freewheel

Application Example:

• During edge trimming, the trimming rollers are powered by the shear’s drive, operating the freewheels in driving mode

• When the next pair of rollers grips the sheet metal strip and pulls it at a higher speed, the inner rings of the freewheels overrun the slower shear drive

• At this stage, the freewheels operate in freewheeling mode

• The use of RIDUVIT® sprags significantly extends the service life of the freewheels

Mounting:

• The customer attachment part is mounted on the external diameter (D)

• The attachment is then bolted to the face

• The shaft tolerance must conform to ISO h6 or j6

• The pilot diameter (D) of the attachment part must have a tolerance of ISO H7 or J7

♦ ♦ Images are for representation purposes only

Part Number - FB 82 SF RINGSPANN

Category - Complete Freewheels FB

Principal Dimensions & Specifications (Metric):

Standard Bore Diameter (d) * - 50 mm

Maximum Bore Diameter (d) * - 50 mm

Outer Diameter (D) - 135 mm

Dimension (F) - 2 mm

Thread (G) ** - M10

Dimension (H) - 16 mm

Dimension (L) - 75 mm

Dimension (T) - 115 mm

Number of Tapped Holes (Z) ** - 12

Weight - 5.8 kg

Type - Standard Type for Universal Use (SF Type)

Nominal Torque (MN) - 1800 Nm

Maximum Speed of Inner Ring Freewheels/ Overruns - 1025 RPM

Maximum Speed of Outer Ring Freewheels/ Overruns - 1450 RPM

Description of Suffix:

SF - Standard Type for Universal Use (SF Type)

Other salient points to be noted:

* Keyway according to DIN 6885

** Z = Number of tapped holes G on pitch circle T

• The maximum transmissible torque is 2 times the specified nominal torque

• Tolerance of keyway width JS10

Features:

• Type: sealed sprag freewheels with integrated ball bearings

• Lubrication: supplied oil-filled and ready for installation

• Eco Option: Available with biodegradable oil upon request

• Variants: Standard model, three enhanced versions designed for extended service life and reliable performance in demanding applications

• Nominal torque capacity up to 160,000 Nm

• Bore sizes up to 300 mm

• A wide selection of standardized bore diameters is available, ensuring short lead times and fast delivery

Application as: Backstop, Overrunning Clutch, Indexing Freewheel

Application Example:

• During edge trimming, the trimming rollers are powered by the shear’s drive, operating the freewheels in driving mode

• When the next pair of rollers grips the sheet metal strip and pulls it at a higher speed, the inner rings of the freewheels overrun the slower shear drive

• At this stage, the freewheels operate in freewheeling mode

• The use of RIDUVIT® sprags significantly extends the service life of the freewheels

Mounting:

• The customer attachment part is mounted on the external diameter (D)

• The attachment is then bolted to the face

• The shaft tolerance must conform to ISO h6 or j6

• The pilot diameter (D) of the attachment part must have a tolerance of ISO H7 or J7

♦ ♦ Images are for representation purposes only