Description

Brand - CPM

Part Number - 2183 - 2439 CPM

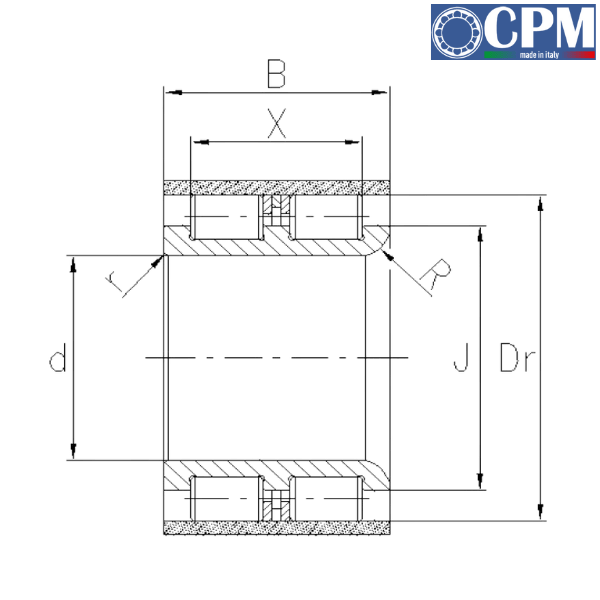

Category - Double Row Full Complement Cylindrical Roller Bearing

Type - A

Type A - 2 Flange Rings and 1 Snap Ring

Principal Dimensions and Load Ratings (Metric):

Inner Diameter (d) - 32 mm

Outer Diameter (Dr) - 46.6 mm

Width (B) - 28 mm

Dimension (J) - 41 mm

Dimension (X) - 22 mm

Chamfer Dimension (R min) - 3 mm

Minimum Chamfer Dimension (r min) - 0.3 mm

Basic Dynamic Radial Load Rating (Cr) - 54.3 kN

Basic Static Radial Load Rating (Cor) - 82.5 kN

Other salient points to be noted:

• Configurations: Available as single-row or multi-row designs, and in both full complement (full-fill) and caged versions

• Space Optimization: Full-fill cylindrical bearings are made with one or more crowns to maximize roller density and space use

• Performance: The caged variant is engineered for superior performance, withstanding very high loads and operating at high speeds

• Coatings: Coatings like chrome, phosphating, galvanizing, or black oxide can be applied as needed for specific technical requirements

• Materials: In most cases bearings are made of typical chromium bearing steel, either full hardening or case hardening

• Dimension: Minimum inner diameter 10 mm to maximum outer diameter 800 mm

• Main Appliccation: Planetary gearboxes, textile machines

♦♦ Images are for representation purposes only

Part Number - 2183 - 2439 CPM

Category - Double Row Full Complement Cylindrical Roller Bearing

Type - A

Type A - 2 Flange Rings and 1 Snap Ring

Principal Dimensions and Load Ratings (Metric):

Inner Diameter (d) - 32 mm

Outer Diameter (Dr) - 46.6 mm

Width (B) - 28 mm

Dimension (J) - 41 mm

Dimension (X) - 22 mm

Chamfer Dimension (R min) - 3 mm

Minimum Chamfer Dimension (r min) - 0.3 mm

Basic Dynamic Radial Load Rating (Cr) - 54.3 kN

Basic Static Radial Load Rating (Cor) - 82.5 kN

Other salient points to be noted:

• Configurations: Available as single-row or multi-row designs, and in both full complement (full-fill) and caged versions

• Space Optimization: Full-fill cylindrical bearings are made with one or more crowns to maximize roller density and space use

• Performance: The caged variant is engineered for superior performance, withstanding very high loads and operating at high speeds

• Coatings: Coatings like chrome, phosphating, galvanizing, or black oxide can be applied as needed for specific technical requirements

• Materials: In most cases bearings are made of typical chromium bearing steel, either full hardening or case hardening

• Dimension: Minimum inner diameter 10 mm to maximum outer diameter 800 mm

• Main Appliccation: Planetary gearboxes, textile machines

♦♦ Images are for representation purposes only