SantEnt: Leading independent distributor of IKO

Introduction

IKO Nippon Thompson is a world-renowned Japanese brand celebrated for its innovation and excellence in manufacturing high-quality motion components. Specialising in needle roller bearings, linear motion guides, and mechatronics, IKO has established itself as a pioneer in developing products that deliver exceptional precision, rigidity, and reliability for the most demanding industrial applications. Their commitment to technological advancement ensures solutions that enhance performance and reduce maintenance across various sectors. With decades of experience, SantEnt is your trusted partner, expertly sourcing and supplying a comprehensive range of genuine IKO products to clients worldwide, ensuring optimal performance for your machinery.

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

IKO at a glance

| Founded |

1950 |

| Headquarters |

Minato City, Tokyo, Japan |

| Leadership |

David Koschitzky |

| Tentative Revenue |

Approx. JPY 87.8 Billion (Fiscal Year 2024) |

| Listed on Stock Market? |

Yes, Tokyo Stock Exchange (TSE: 6480) |

| Parent Organisation(s) |

Nippon Thompson Co., Ltd. |

| Subsidiary Organization(s) |

IKO Nippon Thompson (UK-Ireland), UBC Precision Bearing Co, Ltd, IKO North America, IKO Thompson Bearings Canada, Inc., and IKO Nippon Thompson Europe |

| Ownership |

Family-owned business |

| Other Group Entities or Stakeholders |

NTN Americas, NTN Bearing Corporation of America, Nippon Dic Co., Ltd. |

{"height":27,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

History of IKO

| Year |

Milestone |

| 1950 |

Daiichi-Kogyo Co., Ltd., the predecessor of Nippon Thompson Co., Ltd., was established. |

| 1956 |

Commenced the research, development, and manufacturing of needle roller bearings. |

| 1959 |

Established Himeji Factory in Himeji, Hyogo, and began manufacturing Needle Roller Bearings. |

| 1963 |

Company name was changed to Nippon Thompson Co., Ltd. and was listed on the Tokyo and Nagoya Stock Exchanges. |

| 1978 |

Developed and started selling linear motion rolling guides- Linear Way (currently Linear Way Series). |

| 1996 |

Established Gifu Factory 5 at Gifu Factory Complex. Completed Information System Center at Gifu Factory Complex. |

| 2004 |

Acquired Gifu Prefecture Environmentally Conscious Business Facility Certificate in Gifu area (Gifu Factory Complex, Kasagami MFG. Co., Ltd. and Mugegawa MFG. Co., Ltd.). |

| 2010 |

Innovated and produced the world's smallest linear motion rolling guide, featuring a track rail width of just 1mm. |

| 2017 |

Acquired two companies engaged in manufacturing and sales of Bearings in China; UBC (SHANGHAI) PRECISION BEARING MFG. CO.,LTD. and UBC (SUZHOU) BEARING CO., LTD. (currently a consolidated subsidiary) |

{"height":34,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

IKO Product Portfolio

Linear Motions

| Sub-categories |

Products & Features |

Applications |

Industries |

| Ball Type Rolling Guides |

Linear Way L, Linear Way E, Linear Way U, Low Decibel Linear Way |

High precision, compact design, various sizes and load ratings, smooth motion |

Semiconductor manufacturing, medical devices, packaging machines, measuring instruments |

| Roller Type Rolling Guides |

Linear Roller Way Super X, Linear Roller Way G |

Ultra-high rigidity, high load capacity, superior running accuracy |

Machine tools, industrial robots, heavy-duty material handling, aerospace equipment |

| Ball Spline Rolling Guides |

Ball Spline G, Stroke Ball Spline, Rotary Ball Spline |

High torque transmission, anti-friction linear and rotary motion, compact structure |

SCARA robots, automatic tool changers (ATC), assembly equipment, wire winders |

| Other Linear Motion Guides |

Precision Linear Slide Unit, Roller Way, Anti-Creep Cage Crossed Roller Way |

Pre-assembled slide units, high accuracy, non-recirculating elements for short strokes |

Optical measuring equipment, disk read/write devices, office equipment, precision machinery |

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Rotary Motions

| Sub-categories |

Products & Features |

Applications |

Industries |

| Cam Followers |

Standard, Eccentric, Solid Eccentric, Heavy Duty, C-Lube options |

High rotational performance, thick outer ring to bear impact loads, stud or yoke type |

Indexing mechanisms, conveyor systems, automated machinery, packaging equipment |

| Roller Followers |

Separable, Non-separable types |

High load capacity, designed for outer ring rotation, low friction |

Rocker arms, cam mechanisms in automotive engines, transfer systems |

| Crossed Roller Bearings |

Standard, High Rigidity, Slim Type, Mounting Holed |

Cylindrical rollers in a V-groove, handles complex loads from all directions |

Industrial robot joints, rotary tables of machining centers, medical scanners |

| Shell Type Needle Roller Bearings |

Caged, Full Complement |

Thin-walled outer ring, high load capacity in a small space, suitable for mass production |

Automotive transmissions, power tools, two-cycle engines, office automation equipment |

| Machined Type Needle Roller Bearings |

With/without inner ring, solid or split cage |

High precision and rigidity, can handle heavy loads and high-speed rotation |

Machine tool spindles, printing presses, construction machinery, reduction gears |

| Combined Needle Roller Bearings |

Radial & Thrust bearing combination |

Accommodates both radial and axial loads simultaneously in one compact unit |

Machining center vertical columns, indexing tables, gearboxes |

| Inner Rings |

Hardened and ground steel rings |

Serve as inner raceway for shell type and machined needle roller bearings |

Universal joints, applications where shafts cannot be hardened |

| Thrust Bearings |

Needle Roller, Roller Thrust Bearings |

High axial load capacity with minimal axial height |

Automotive transmissions, machine tool turrets, steering pivots, clutches |

| Roller Bearings |

Cylindrical Roller Bearings |

Handles high radial loads and high speeds, low friction |

Electric motors, pumps and compressors, industrial gearboxes |

{"height":11,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Plain Bearings

| Sub-categories |

Products & Features |

Applications |

Industries |

| Spherical Bushings |

GE Series, SBB Series, Maintenance-free types (C-Lube) |

Self-aligning capability, accommodates misalignment, handles heavy radial loads |

Construction machinery joints, hydraulic cylinder pivots, food processing equipment |

| Rod Ends |

Male/Female threads, with/without lubrication holes, Pilloball series |

Links mechanisms, transfers oscillating motion, accommodates misalignment |

Control linkages, steering systems, robotics, packaging machinery |

{"height":11,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Mechatronics

| Sub-categories |

Products & Features |

Applications |

Industries |

| Ball Screw Drive Positioning Tables |

Precision Positioning Table (TU), Alignment Table (AT) |

High-precision ball screw, integrated motor and guides, compact and rigid |

Semiconductor inspection, component assembly, precision positioning tasks |

| Linear Motor Drive Positioning Tables |

Precision Positioning Table (TL) |

Coreless linear motor, direct drive for high speed and acceleration, excellent accuracy |

High-speed pick-and-place, vision inspection systems, dispensing equipment |

| Specialised Stages |

Nano Linear (NT), Alignment Stage (SA) |

Nanometer-level positioning, multi-axis alignment capabilities |

FPD manufacturing, biotechnology, optical device alignment, R&D labs |

{"height":11,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Maintenance-free C-Lubes

| Sub-categories |

Products & Features |

Applications |

Industries |

| Ball/Roller Linear Guides |

C-Lube Linear Way, C-Lube Linear Roller Way Super X |

Built-in lubrication system, maintenance-free for 5 years or 20,000 km |

Cleanroom environments, food processing, medical equipment, any application where re-lubrication is difficult or undesirable |

| Ball Spline & Cam Followers |

C-Lube Ball Spline G, C-Lube Cam Follower |

Thermosetting solid lubricant provides long-term, contamination-free lubrication |

Automated assembly lines, packaging machinery, textile manufacturing |

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Acquisitions & Group Companies

{"height":11,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Based in the Netherlands, this company serves as the European headquarters, coordinating sales, warehousing, and technical services across the continent. This central hub allows IKO to provide localised support and efficient logistics to a diverse European market.

{"height":34,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Stay updated with IKO

Stay informed about:

- The latest product innovations.

- Technological advancements.

- Corporate news from this brand.

For the most current information, press releases, and media updates.

Acquisitions & Mergers - Media Coverage And so much more, on the link below!

Why choose SantEnt for your IKO requirements?

-

Vast Inventory, Global Sourcing & Competitive Pricing

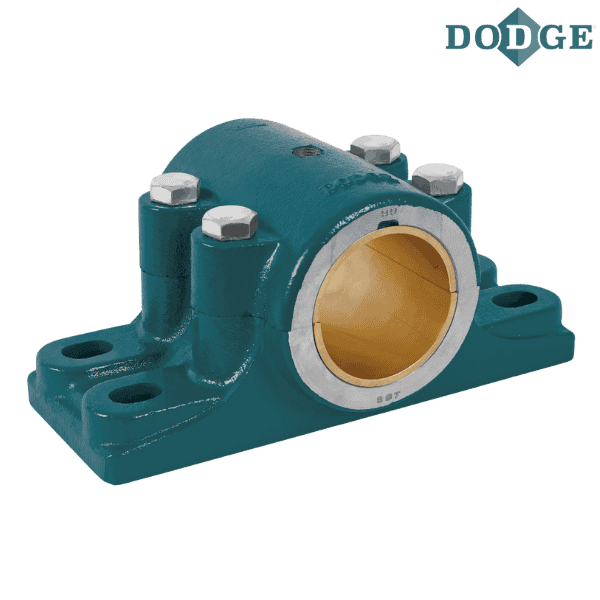

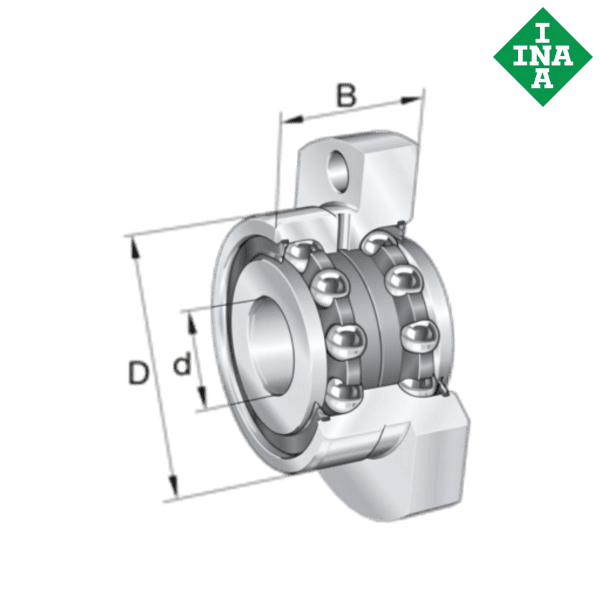

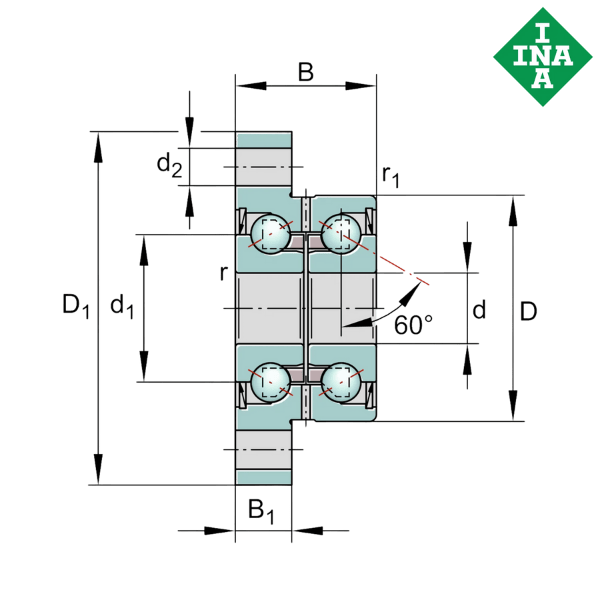

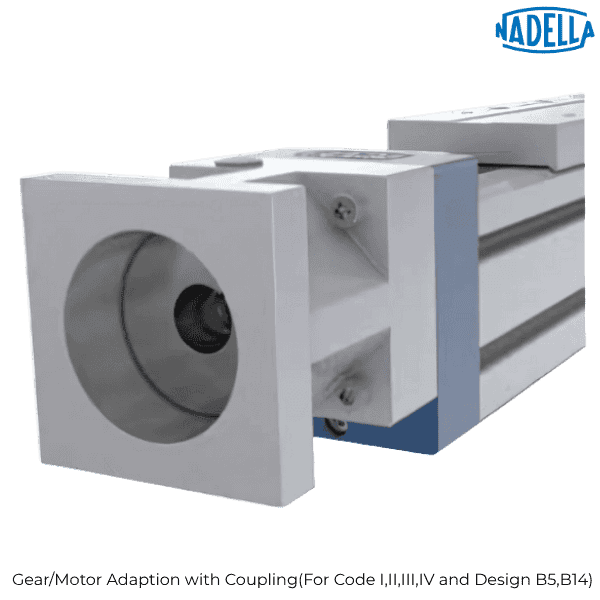

With over 60,000 bearings in stock and a strong relationship with the manufacturer & other distributors, we ensure no IKO product is too far from you. It is always competitively priced through our extensive collaborations and strong relationships with our supply chain stakeholders to achieve the best prices for IKO products. Additionally, we are Authorised Distributors of Schaeffler, FAG, INA, FYH, Optibelt and Dodge.

-

Genuine Products Guaranteed over Decades of Trust

As a renowned Bearing distribution company established in 1977, our third generation is equipped with Engineering, Technology & Business Management education as well as corporate experience. This enables us to deliver genuine products with professionalised services to our rapidly growing global customer base spread across 60 countries and 6 continents.

-

Robust Technical & After-Sales Support

Owing to the criticality of the products we deal in, our responsibility starts much before the supply of products, by way of Technical Support in identifying the right spare parts for the desired application, eliminating instances of failure or premature breakdown. Even after supply, we closely work with our customers in case of any queries or support requirements such as product warranty, installation & storage guidance to cite a few.