How to choose right type of bearing for your application?

A bearing is a mechanical constituent whose function is to guide a rotating assembly. The bearing therefore allows the rotation of one element relative to another. Bearings are therefore high-precision parts that allow equipment to move at different speed levels by efficiently transporting notable loads. They must offer high precision and durability, as well as the possibility of working at high speeds with minimal noise and vibration. This type of device is found in all applications such as, for example, the automotive industry, the aerospace sector, construction equipment, machine tools, etc.

There are several types of bearings, the four main types are: ball bearings, cylindrical roller bearings, tapered roller bearings and needle bearings. While ball bearings are the most common mechanisms, each device has its advantages and disadvantages. That is why we recommend that you compare each of these bearings to determine which is the ideal system for your requirements. In this blog you will find various important elements to be considered and effective tips to choose the right type of bearing for your application.

When choosing a bearing, you must consider several important factors. The first factor to consider is the load that the bearing can support. There are two types of loads:

– axial load: parallel to the axis of rotation

– radial load: perpendicular to the axis

Important Elements to be considered while buying a Bearing :

- Each type of bearing is specifically designed to support an axial or radial load. Some bearings can support both loads: in this case we refer to a combined load. If you have to support a combined load, for example, we recommend that you choose a tapered roller bearing. If you need a bearing capable of withstanding a high radial load, then we recommend a cylindrical roller bearing. On the other hand, if your bearing needs to support lighter loads a ball bearing might be sufficient as they are often less expensive.

- Rotation speed is another element that should be considered. Some bearings can withstand high speeds. The presence of a cage for cylindrical roller bearings and needle bearings allow for greater speeds than bearings without a cage.

- However, the choice of a higher speed is sometimes made at the expense of the load. You should also consider the possible presence of misalignment; some bearings are not suitable for this situation, such as double row ball bearings.

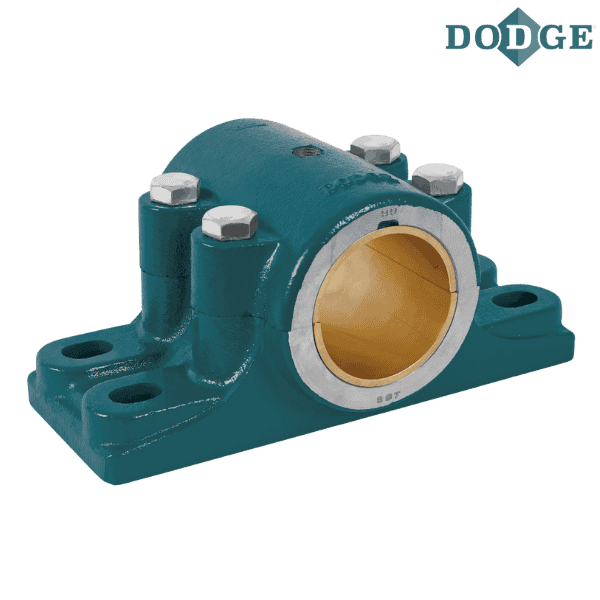

- You will therefore need to pay attention to the bearing construction: insert and spherical bearings make it easy to support these misalignments. We suggest that you lean towards bearings with automatic alignment which automatically corrects alignment defects caused by shaft bending or installation errors.

Tips for buying the Right type of bearings:

-

Operating conditions are very important when choosing the ideal bearing. It is thus necessary to analyze the environment you will be using the bearing in. Your bearing may be subject to a number of contaminations. Some uses can lead to noise disturbance, impact and/or vibration. Your bearing must therefore withstand this impact on the one hand and not be an inconvenience on the other.

- Another essential element to consider is the bearing life. Several factors, such as speed or repeated use, can impact the bearing life. Choosing a sealing system is essential in order to ensure the correct and long-lasting operation of a bearing; it is therefore important to ensure that the bearing is always well-protected from any impurities and external agents, such as dust, water, corrosive fluids or even used lubricants.

- This choice depends on the type of lubricant, the ambient conditions, the fluid pressure and the rotation speed. For your Knowledge, the fluid pressure is a determining factor in the choice of sealing system. If the pressure is high (in the range of 2-3 bars for example) a mechanical seal is ideal. Otherwise, the choice will be directly linked to the type of lubricant, grease or oil. For example, for grease lubrication the most commonly used solutions are: deflectors or washers, narrow passages that are machined or with grooves; in the case of oil lubrication the sealing system is often accompanied by the presence of a groove for oil recovery.

- Then you will need to pay attention to how the bearings are assembled. If two bearings are too close together, you should use the O-assembly method so that the bearings do not interfere with each other. If this is not the case then the X-assembly method is perfectly suitable.

- Finally, each bearing has specific dimensions. These dimensions, expressed in mm, are subject to international standards. We therefore advise you to pay attention to the bore of the bearing, i.e. the inner diameter.

How to select Right type of Bearing according to load :

Let us now examine general selection criteria for each type of bearing which will help to choose the right type of bearing for your Application.

- Deep groove is normally used for radial and thrust loads.

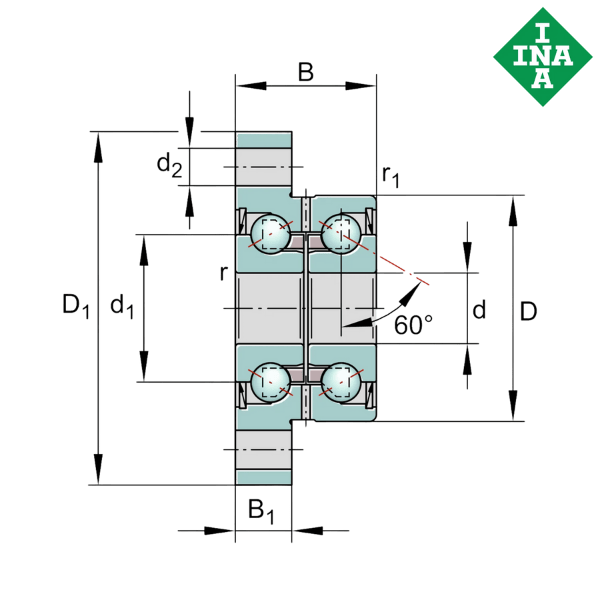

- Angular Contact Ball Bearings – are designed to support combined radial and thrust loads or heavy thrust loads depending on the contact-angle magnitude. Bearings having large contact angles can support heavier thrust loads.

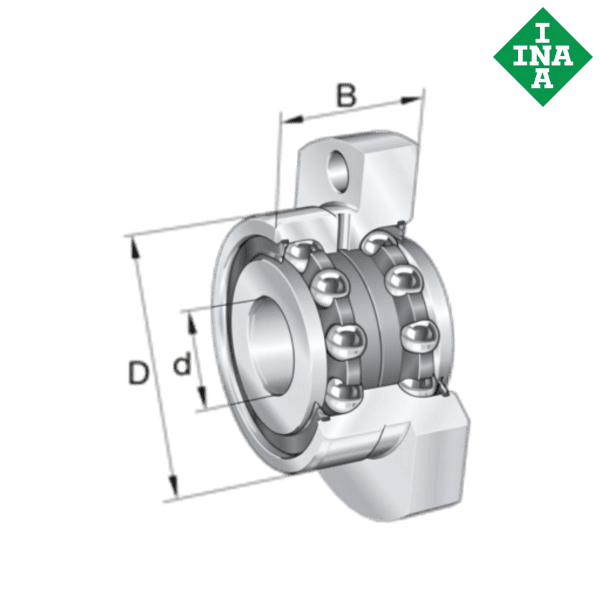

- Self – Aligning Ball Bearings – may be used for primarily radial loads where self-alignment ±4° is required. Extra care should taken while selecting these types of bearing as excessive misalignment or thrust load greater than 10% of radial load can cause early failure.

- Spherical Roller Bearings – are excellent for heavy radial loads and moderate thrust. Their internal self-aligning feature is useful in many applications such as HVAC fans.

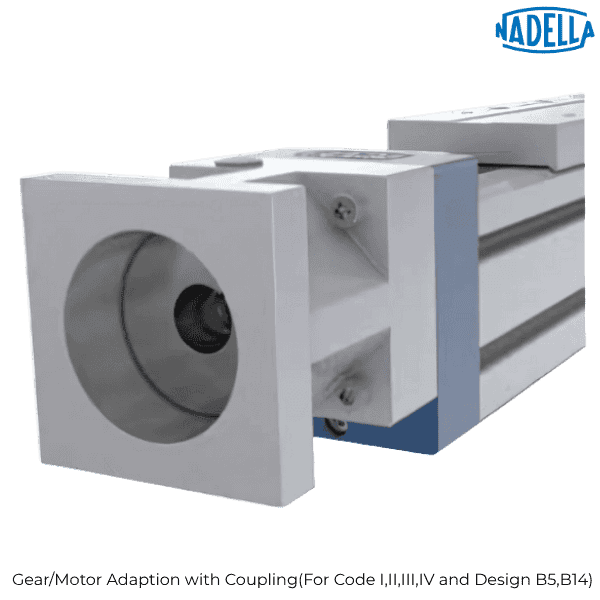

- Cylindrical roller Bearings – utilize cylinders with approximate length/diameter ratio ranging from 1 : 1 to 1 : 3 as rolling elements. Normally used for heavy radial loads. Especially useful for free axial movement of the shaft.

- Taper Roller Bearings – are used for heavy radial and thrust loads. The bearing is designed so that all elements in the rolling surface and the raceways intersect at a common point on the axis thus true rolling is obtained. Where maximum system rigidity is required, the bearings can be adjusted for a preload.

- Thrust Ball Bearings – may be used for low-speed applications where other bearings carry the radial load.

- Straight-Roller Thrust Bearing – these bearings are made of a series of short rollers to minimize the skidding, which causes twisting, of the rollers. They may be used for moderate speeds and loads.

- Needle Bearings – these bearings have rollers whose length is at least 4times their diameter. They are most useful where space is a factor and are available with or without inner race. If shaft is used as inner race, it must be hardened and ground. Full-complement type is used for high loads, oscillating, or slow speeds. Cage type should be used for rotational motion. They cannot support thrust loads.

Who are we?

Our Comprehensive knowledge of product lines provide support to our customers through cost efficiencies, selecting the correct product and high operative effectiveness. We are known across various locations for being the most cost-effective, genuine and timely solution provider for all your industrial needs.

We are the Santent Group of Companies, committed to serve global markets in Asia and the Middle East with 25+ global brands, and over 10,000 unique SKUs. You can rely on us for a fast and cost effective delivery of your goods.