SantEnt: Leading independent distributor of Askubal

Introduction

Askubal, a brand synonymous with "Made in Germany" quality, has been a leading manufacturer of high-precision rod ends, spherical plain bearings, and specialised bearing solutions since 1938. Renowned for their robust engineering and adherence to stringent quality standards, Askubal products are trusted in demanding applications across mechanical engineering, automotive, and automation industries. Their portfolio, featuring everything from maintenance-required rod ends to advanced bearing units, showcases a commitment to performance and durability. With decades of experience, SantEnt is your reliable global partner for sourcing and supplying the complete range of Askubal products, ensuring authenticity and timely delivery.

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Askubal at a glance

| Founded |

1930 |

| Headquarters |

Korntal-Munchingen, Germany |

| Leadership |

Frank Seyfert, Stefan Seyfert |

| Tentative Revenue |

Not publicly available |

| Listed on Stock Market? |

No |

| Parent Organisation(s) |

None |

| Subsidiary Organization(s) |

None |

{"height":27,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

History of Askubal

| Year |

Milestone |

| 1930 |

Artur Seyfert establishes the company in Stuttgart-Feuerbach, Germany. |

| 1960 |

The company pioneers its first line of ASK unibal joints and rod ends. |

| 1977 |

Operations are relocated to a new, larger production facility in Korntal-Munchingen. |

| 1993 |

The third generation, Frank and Stefan Seyfert, assume leadership of the company. |

| 2005 |

Askubal celebrates its 75th anniversary, marking a long history of manufacturing excellence. |

| 2016 |

A new generation of maintenance-free rod ends featuring an innovative T-profile plain bearing is launched. |

.

Askubal Product Portfolio

Rod Ends

| Sub-categories |

Products & Features |

Applications |

Industries |

| Male Thread, Maintenance Required |

External thread; steel-on-steel sliding surface |

General mechanical linkages, levers, agricultural machinery |

Requires periodic lubrication |

| Male Thread, Maintenance Required, Sealed |

External thread; steel-on-steel; sealed for protection |

Contaminated or wet environments; construction equipment |

Requires periodic lubrication |

| Male Thread, Maintenance-Free |

External thread; self-lubricating liner (e.g., PTFE) |

Packaging machinery, food processing, clean environments |

Maintenance-free |

| Male Thread, Maintenance-Free, Sealed |

External thread; self-lubricating; sealed for protection |

Outdoor applications, automotive, high-debris areas |

Maintenance-free |

| Male Thread with Ball Bearings |

External thread; integrated precision ball bearing |

High-speed, low-load linkages; printing presses, robotics |

Low friction; may require grease |

| Male Thread with Roller Bearings |

External thread; integrated roller bearing for high loads |

Heavy-duty linkages; high radial load applications |

High load capacity; requires grease |

| Female Thread, Maintenance Required |

Internal thread; steel-on-steel sliding surface |

Control rods, steering links, industrial equipment |

Requires periodic lubrication |

| Female Thread, Maintenance Required, Sealed |

Internal thread; steel-on-steel; sealed for protection |

Dirty or corrosive environments; off-road vehicles |

Requires periodic lubrication |

| Female Thread, Maintenance-Free |

Internal thread; self-lubricating liner (e.g., PTFE) |

Automation, textile machinery, applications requiring no lube |

Maintenance-free |

| Female Thread, Maintenance-Free, Sealed |

Internal thread; self-lubricating; sealed for protection |

Marine applications, washdown environments |

Maintenance-free |

| Female Thread with Ball Bearings |

Internal thread; integrated precision ball bearing |

Precision control systems, sorting equipment |

Low friction; may require grease |

| Female Thread with Roller Bearings |

Internal thread; integrated roller bearing for high loads |

Heavy industrial machinery, high-impact applications |

High load capacity; requires grease |

| Hydraulic Rod End, Female Thread |

Internal thread; robust body for hydraulic piston rods |

Connecting hydraulic/pneumatic cylinders to machinery |

Depends on bearing type |

| Hydraulic Rod End, Square Welding End |

Weldable square shank; forged or cast body |

Mounting hydraulic cylinders via direct welding |

Depends on bearing type |

| Hydraulic Rod End, Round Welding End |

Weldable round shank; robust construction |

Attaching hydraulic cylinders where welding is preferred |

Depends on bearing type |

{"height":33,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Spherical Plain Bearings

| Sub-categories |

Products & Features |

Applications |

Industries |

| Maintenance Required |

Steel-on-steel sliding contact surfaces; high load capacity |

Heavy industrial equipment, construction machinery, mining |

Requires periodic lubrication |

| Maintenance-Free |

Self-lubricating liner (e.g., PTFE); consistent friction |

Food processing, packaging, applications where lube is impractical |

Maintenance-free |

| Maintenance Required, Sealed |

Steel-on-steel with integrated seals (e.g., 2RS) |

Agricultural machinery, off-road vehicles, contaminated areas |

Requires periodic lubrication |

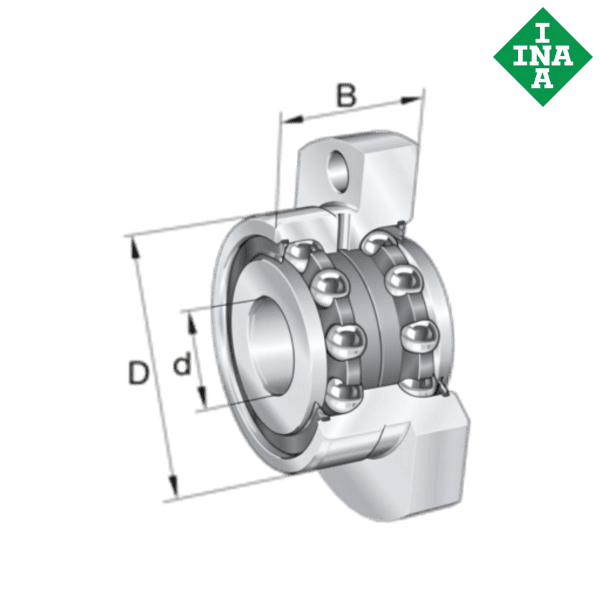

| With Ball Bearings (Self-Aligning) |

Inner ring with two rows of balls; accommodates misalignment |

High-speed shafts, fans, textile machinery, conveyors |

Lower friction; requires grease |

{"height":34,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Rolling Bearings

| Sub-categories |

Products & Features |

Applications |

Industries |

| Self-Aligning Ball Bearings |

Two rows of balls; spherical outer raceway; compensates for shaft/housing misalignment. |

Agricultural machinery, fans, long shafts, textile machines. |

Typically requires grease; available in sealed versions. |

| Deep Groove Ball Bearings |

Versatile, simple design; handles radial and some axial loads; suitable for very high speeds. |

Electric motors, household appliances, automotive wheels, conveyors. |

Often sealed and greased for life; otherwise, requires grease. |

| Self-Aligning Roller Bearings |

Two rows of barrel-shaped rollers; high radial load capacity; tolerates heavy misalignment. |

Heavy industrial machinery, mining equipment, paper mills, large gearboxes. |

Requires grease or oil lubrication due to high loads. |

| Tapered Roller Bearings, Single-Row |

Tapered rollers and raceways; handles high radial and axial loads in one direction. |

Vehicle wheel hubs, gearboxes, industrial transmissions, axles. |

Requires grease or oil; proper preload is critical for performance. |

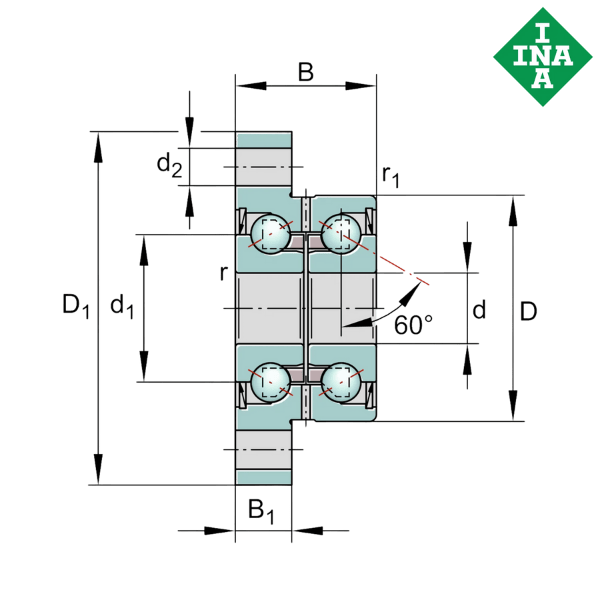

| Angular Contact Ball Bearings, Single-Row |

Offset raceways; supports combined (radial & axial) loads; high-speed capability. |

Pumps, compressors, high-performance gearboxes, machine tool applications. |

Requires grease or oil; typically mounted in pairs. |

| Spindle Bearings |

High-precision angular contact bearing; optimized for extreme speed, accuracy, and rigidity. |

High-speed machine tool spindles (milling, grinding, turning). |

Requires specialized grease or oil-air lubrication systems. |

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Bearing Units

| Sub-categories |

Products & Features |

Applications |

Industries |

|

Pillow Block Units (UCP, UKP, UCPA, UCPH, UCPW, BPP, KP, UP, MUP, MUCP, PUCP, etc.) |

Cast iron, pressed steel, or thermoplastic housing; two mounting holes; supports rotating shafts. |

Conveyor systems, agricultural machinery, fans, food and beverage processing. |

Relubricatable via grease nipple; sealed for life in some thermoplastic versions. |

Square Flange Units (4-Bolt)

(UCF, UKFC, UCFS, MUCF, PUCF) |

Square-shaped housing with four mounting holes; for perpendicular mounting on surfaces. |

Industrial machinery frames, textile equipment, processing plant machinery. |

Relubricatable via grease nipple; provides rigid support. |

Oval Flange Units (2-Bolt)

(UCFL, UKFL, BPFL, KFL, UFL, MUCFL, PUFL, etc.) |

Oval or diamond-shaped housing with two mounting holes; for limited space applications. |

Light-duty conveyors, packaging equipment, applications where space is restricted. |

Relubricatable via grease nipple; available in cast iron, steel, and thermoplastic. |

Round & Cartridge Units (3/4-Bolt)

(UCFC, UCC, MUCFPL) |

Cylindrical outer surface (cartridge) or round flange; fits into machined housing bores.achine tools, conveyor rollers, applications requiring precise housing alignment. |

Machine tools, conveyor rollers, applications requiring precise housing alignment. |

Relubricatable via grease nipple; allows for controlled fit. |

Take-Up Units

(UCT, UKT, MUCT, PUCT) |

Housed in a sliding frame; allows for conveyor belt tensioning and shaft adjustment. |

Conveyor systems, belt-driven machinery, applications needing adjustable shafts. |

Relubricatable; designed for linear adjustment within a guide frame. |

Hanger & Specialty Units

(KHLCTE, BLCTE) |

Specialized housings for suspending shafts or unique mounting configurations. |

Screw conveyors, agricultural augers, overhead material handling systems. |

Relubricatable; designed for specific mounting requirements. |

{"height":33,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Cam Followers

| Sub-categories |

Products & Features |

Applications |

Industries |

| Stud Type Cam Followers (KR, KRV, MCF, MCFR, MCFD) |

Integrated stud for direct mounting; cage-guided (KR) or full-complement (KRV) needles; often with a crowned outer ring. |

Cam drives, indexing mechanisms, linear motion systems, automation equipment. |

Relubricatable via lubrication holes in the stud head and body. |

| Yoke Type Cam Followers (Track Rollers) (NATR, NATV, MCYR, MCYRD, MCYRR) |

Designed for mounting on a shaft or pin; cage-guided (NATR) or full-complement (NATV) for higher loads. |

Track rollers, guide rollers, support rollers in conveyor systems and material handling. |

Relubricatable via the inner ring; some versions include axial guidance. |

{"height":33,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Shaft-Hub-Connections

|

Sub-categories

|

Products & Features |

Applications |

Industries |

| Internal Locking Assemblies (Standard) (Type 110) |

Non-self-centering; high transmissible torque; requires a guide for concentricity. |

Connecting gears, sprockets, and pulleys to shafts in general machinery. |

Generally maintenance-free; bolts may require re-torquing after initial run-in. |

| Internal Locking Assemblies (Self-Centering) (Types 130, 131, 132, 133, 134) |

Self-centering design; excellent concentricity; various torque/pressure ratings. |

High-precision applications; machine tools, conveyor pulleys, gearboxes. |

Maintenance-free after installation; bolts must be tightened to specified torque. |

| External Shrink Discs (Type 200) |

External mounting; compresses hollow shafts/hubs; very high torque capacity. |

Connecting hollow shaft gearboxes, heavy-duty conveyor drums, large levers. |

Maintenance-free; provides a robust, backlash-free connection. |

| Cone Clamping Element (Type 300) |

Simple two-part cone design; light to medium torque; easy installation and removal. |

Fastening small gears, timing belt pulleys, cams, and other light-duty components. |

Maintenance-free; offers a compact and cost-effective solution. |

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Clevises and Bolts

| Sub-categories |

Products & Features |

Applications |

Industries |

| Clevises and Bolts |

Standardized components (DIN 71752), high-strength steel. |

Connecting rod ends to levers and cylinders, creating pivot joints. |

Pneumatics, Hydraulics, General Machine Building. |

{"height":24,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Steel Balls

| Sub-categories |

Products & Features |

Applications |

Industries |

| Steel Balls |

High-precision grades, hardened chrome steel for durability. |

Ball bearings, check valves, locking mechanisms. |

Bearing Manufacturing, Automotive, Hydraulics. |

{"height":52,"color":{"hue":213,"brightness":0.83,"saturation":1,"alpha":0},"hidden":false,"locked":false,"blockName":"Spacer"}

Why choose SantEnt for your Askubal requirements?

-

Vast Inventory, Global Sourcing & Competitive Pricing

With over 60,000 bearings in stock and a robust global network, SantEnt ensures that no Askubal product is out of reach. Our strong relationships with manufacturers and distributors allow us to source efficiently and offer highly competitive pricing on all Askubal products. Additionally, as Authorised Distributors of Schaeffler, FAG, INA, FYH, Optibelt, and Dodge, our sourcing capabilities are second to none.

-

Genuine Products Guaranteed over Decades of Trust

Established in 1977, SantEnt is a trusted name in the bearing distribution industry. Now led by a third generation equipped with modern engineering, technology, and business management expertise, we guarantee 100% genuine products. This commitment to quality and professionalism serves our rapidly growing customer base across 60+ countries and 6 continents.

-

Robust Technical & After-Sales Support

We understand the critical nature of industrial spares. Our responsibility begins long before a sale, offering expert technical support to help you identify the precise Askubal part for your application, preventing premature failure. After the supply, we remain your dedicated partner, providing assistance with product warranties, installation guidance, and any other support you may require.