INA, another brand under the Schaeffler Group alongside FAG, produces various types of washers designed to complement their bearing products. Washers play a crucial role in bearing assemblies, providing support, alignment, and load distribution. Here are some common types of washers used with bearings:

-

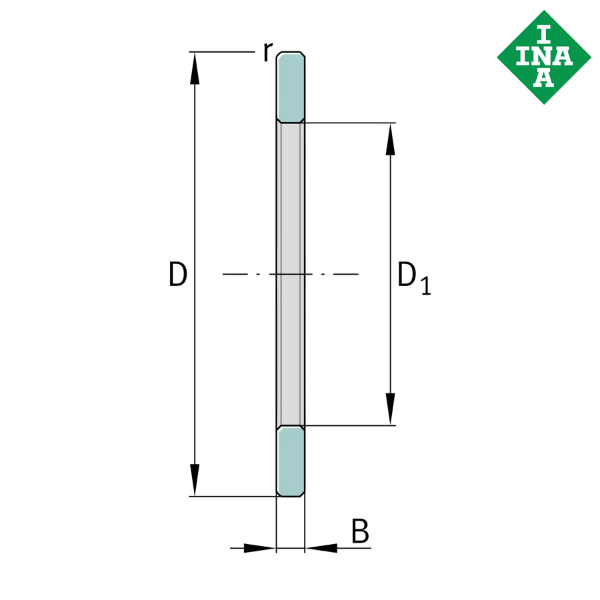

Thrust Washers: These washers are used in conjunction with thrust bearings to provide axial support and prevent axial movement of the bearing assembly. They typically have a flat design and are placed between the bearing and adjacent components.

-

Needle Roller Thrust Bearing Washers: Designed for use with needle roller thrust bearings, these washers have specially designed raceways to accommodate the needle rollers' movement. They help distribute the load evenly and prevent damage to the mating surfaces.

-

Axial Cylindrical Roller and Cage Assemblies: These assemblies consist of axial cylindrical roller and cage components, along with washers. They are used in applications where high axial loads need to be supported and where space is limited.

-

Shaft Locating Washers: These washers are used in combination with cylindrical roller bearings to locate the shaft axially in one direction. They are typically used as non-locating bearings on the opposite side of the bearing to the locating bearing.

-

Housing Locating Washers: Similar to shaft locating washers, these washers are used in combination with cylindrical roller bearings to locate the housing axially in one direction. They are typically used as non-locating bearings on the opposite side of the bearing to the locating bearing.

-

Centering Washers: These washers are used to center the bearing components within the housing or on the shaft. They help ensure proper alignment and reduce the risk of misalignment-induced damage.

-

Sealing Washers: These washers are designed to provide a seal between the bearing and the surrounding environment, preventing contamination and retaining lubricant within the bearing assembly. They are commonly used in applications where ingress of dirt, moisture, or other contaminants is a concern.

These are some of the common types of washers used with bearings, including those produced by INA. The specific type of washer required will depend on the bearing type, application requirements, and operating conditions.